What’s a Big Freezer Called? Your Guide to Commercial and Industrial Freezers

Navigating the world of refrigeration can be confusing, especially when you’re dealing with larger-than-life freezers. You’re probably wondering, “What’s a big freezer called?” and perhaps even more importantly, which type is right for your needs. This comprehensive guide will explore the various names, types, applications, and considerations for large-scale freezers, providing you with the expert knowledge you need to make informed decisions. We’ll delve into the nuances of these powerful cooling systems, ensuring you understand the key differences and benefits of each type. From walk-in freezers to blast chillers, we’ll cover it all. This isn’t just a simple definition; it’s a deep dive into the world of commercial and industrial refrigeration.

Understanding Large Freezer Terminology

While the simple answer to “what’s a big freezer called” might seem straightforward, the reality is more nuanced. Several terms describe large freezers, each with specific connotations and applications. Understanding these terms is crucial for effective communication and informed purchasing decisions.

Walk-In Freezers: The Cold Storage Staple

Walk-in freezers, as the name suggests, are large, enclosed spaces designed for storing perishable goods at freezing temperatures. They are commonly used in restaurants, supermarkets, warehouses, and other businesses that require significant frozen storage capacity. Walk-in freezers offer substantial storage volume and can be customized to fit specific needs and space constraints.

* **Construction:** Typically constructed with insulated panels, walk-in freezers maintain consistent temperatures and minimize energy consumption.

* **Temperature Control:** Precise temperature control is essential for preserving the quality of frozen goods. Walk-in freezers are equipped with sophisticated refrigeration systems to maintain consistent temperatures, often down to -20°F (-29°C).

* **Customization:** Walk-in freezers can be tailored to specific needs, with options for shelving, lighting, and door configurations.

Reach-In Freezers: Versatile and Accessible

Reach-in freezers are smaller than walk-in freezers but offer a convenient and accessible way to store frozen goods. They are commonly found in restaurants, convenience stores, and other businesses where quick access to frozen items is essential. While technically smaller than “big freezers”, larger reach-in units can still offer substantial storage.

* **Types:** Reach-in freezers come in various configurations, including single-door, double-door, and glass-door models.

* **Accessibility:** The primary advantage of reach-in freezers is their ease of access. Employees can quickly retrieve frozen items without entering a separate cold storage area.

* **Space Efficiency:** Reach-in freezers are designed to maximize storage capacity within a compact footprint.

Blast Freezers: Rapid Cooling for Optimal Preservation

Blast freezers, also known as shock freezers, are designed to rapidly cool food items to extremely low temperatures. This rapid cooling process minimizes ice crystal formation, preserving the texture, flavor, and nutritional value of the food. Blast freezers are essential for preserving high-quality frozen foods.

* **Speed:** Blast freezers can cool food items from cooking temperatures to freezing temperatures in a matter of hours, significantly faster than conventional freezers.

* **Quality Preservation:** The rapid cooling process minimizes ice crystal formation, which can damage the cellular structure of food and compromise its quality.

* **Applications:** Blast freezers are commonly used in commercial kitchens, food processing plants, and other businesses where rapid cooling is essential.

Industrial Freezers: Large-Scale Solutions for Mass Production

Industrial freezers are the largest and most powerful type of freezer, designed for large-scale food processing and storage. These freezers are used in food manufacturing plants, distribution centers, and other facilities that require massive frozen storage capacity. Industrial freezers are often custom-built to meet specific needs and can incorporate advanced features such as automated loading and unloading systems.

* **Scale:** Industrial freezers can store thousands of pounds of frozen goods at a time.

* **Automation:** Many industrial freezers incorporate automated systems for loading, unloading, and inventory management.

* **Energy Efficiency:** Due to their size and complexity, energy efficiency is a critical consideration for industrial freezers. Advanced insulation and refrigeration technologies are used to minimize energy consumption.

The Science Behind Freezing and Preservation

Understanding the science behind freezing is crucial for appreciating the importance of proper freezer selection and operation. Freezing temperatures inhibit the growth of microorganisms and slow down enzymatic reactions that cause food spoilage. However, the freezing process itself can also impact the quality of food.

* **Ice Crystal Formation:** When water freezes, it forms ice crystals. The size and distribution of these ice crystals can affect the texture and quality of frozen food. Rapid freezing, as achieved by blast freezers, minimizes ice crystal formation, resulting in a superior product.

* **Enzyme Activity:** Enzymes are biological catalysts that can cause food spoilage. Freezing temperatures slow down enzyme activity, but some enzymes may remain active even at freezing temperatures. Blanching vegetables before freezing helps to deactivate these enzymes and preserve their quality.

* **Freezer Burn:** Freezer burn occurs when moisture evaporates from the surface of frozen food, causing it to become dry and discolored. Proper packaging and sealing can help to prevent freezer burn.

Selecting the Right Large Freezer for Your Needs

Choosing the right large freezer depends on several factors, including the volume of goods to be stored, the frequency of access, and the specific requirements of your business. Here are some key considerations:

* **Storage Capacity:** Determine the amount of frozen storage space you need. Consider both your current needs and your anticipated future growth.

* **Temperature Requirements:** Ensure that the freezer can maintain the appropriate temperature range for the types of goods you will be storing.

* **Energy Efficiency:** Look for energy-efficient models to minimize operating costs.

* **Space Constraints:** Consider the available space and choose a freezer that fits comfortably within your facility.

* **Budget:** Establish a budget and compare prices from different manufacturers.

Leading Manufacturers of Large Freezers

Several reputable manufacturers offer high-quality large freezers. Some of the leading brands include:

* **Hussmann:** Hussmann is a leading manufacturer of refrigeration equipment for supermarkets, convenience stores, and other businesses.

* **Hillphoenix:** Hillphoenix offers a wide range of refrigeration solutions, including walk-in freezers, reach-in freezers, and display cases.

* **Zero Zone:** Zero Zone specializes in energy-efficient refrigeration systems for supermarkets and other food retailers.

* **Killion:** Killion is a leading manufacturer of industrial freezers for food processing and storage.

Refrigeration Systems: The Heart of the Freezer

The refrigeration system is the heart of any freezer, responsible for extracting heat and maintaining the desired temperature. Understanding the different types of refrigeration systems is crucial for selecting the right freezer for your needs.

* **Vapor-Compression Refrigeration:** This is the most common type of refrigeration system, used in most walk-in freezers and reach-in freezers. Vapor-compression systems use a refrigerant to absorb heat from the freezer and release it outside.

* **Absorption Refrigeration:** Absorption refrigeration systems use heat as their energy source, making them a good option for businesses that have access to waste heat. These are less common than vapor-compression systems.

* **Cryogenic Refrigeration:** Cryogenic refrigeration systems use extremely low temperatures to freeze food items rapidly. These systems are used in specialized applications such as flash freezing.

Maintaining Your Large Freezer for Optimal Performance

Proper maintenance is essential for ensuring the long-term performance and reliability of your large freezer. Regular maintenance can help to prevent breakdowns, extend the lifespan of your freezer, and minimize energy consumption.

* **Cleaning:** Clean the interior and exterior of your freezer regularly to remove dirt, dust, and debris.

* **Defrosting:** Defrost your freezer regularly to prevent ice buildup, which can reduce its efficiency.

* **Inspecting Door Seals:** Inspect the door seals regularly to ensure that they are tight and prevent air leaks.

* **Checking Refrigerant Levels:** Have a qualified technician check the refrigerant levels periodically to ensure that the refrigeration system is operating properly.

Walk-In Freezers: A Closer Look

Walk-in freezers are a critical component for many businesses that require significant frozen storage. Let’s examine them in more detail.

* **Panel Construction:** Walk-in freezers are typically constructed with insulated panels made of polyurethane or polystyrene foam. These panels provide excellent insulation and help to maintain consistent temperatures.

* **Door Options:** Walk-in freezers can be equipped with various door options, including hinged doors, sliding doors, and strip curtains. The choice of door depends on the frequency of access and the space constraints.

* **Refrigeration Units:** Walk-in freezers can be equipped with self-contained refrigeration units or remote refrigeration units. Self-contained units are easier to install, while remote units are quieter and more energy-efficient.

Blast Freezers: The Key to Superior Frozen Food Quality

Blast freezers are essential for preserving the quality of frozen food. The rapid cooling process minimizes ice crystal formation and preserves the texture, flavor, and nutritional value of the food.

* **Airflow:** Blast freezers use high-velocity air to rapidly cool food items. The airflow is carefully controlled to ensure uniform cooling.

* **Temperature Monitoring:** Blast freezers are equipped with temperature sensors to monitor the temperature of the food items and ensure that they are cooled to the desired temperature.

* **Cycle Time:** The cycle time of a blast freezer depends on the size and density of the food items. Typical cycle times range from a few hours to overnight.

Industrial Freezers: Powerhouses of Frozen Storage

Industrial freezers are the workhorses of the food processing industry, providing massive frozen storage capacity for large-scale operations.

* **Types:** Industrial freezers come in various types, including tunnel freezers, spiral freezers, and plate freezers. Each type is designed for specific applications.

* **Automation:** Industrial freezers often incorporate automated systems for loading, unloading, and inventory management. These systems can significantly improve efficiency and reduce labor costs.

* **Energy Management:** Energy efficiency is a critical consideration for industrial freezers. Advanced insulation and refrigeration technologies are used to minimize energy consumption.

Real-World Applications of Large Freezers

Large freezers are used in a wide range of industries and applications. Here are some examples:

* **Restaurants:** Walk-in freezers and reach-in freezers are essential for storing frozen ingredients and prepared foods in restaurants.

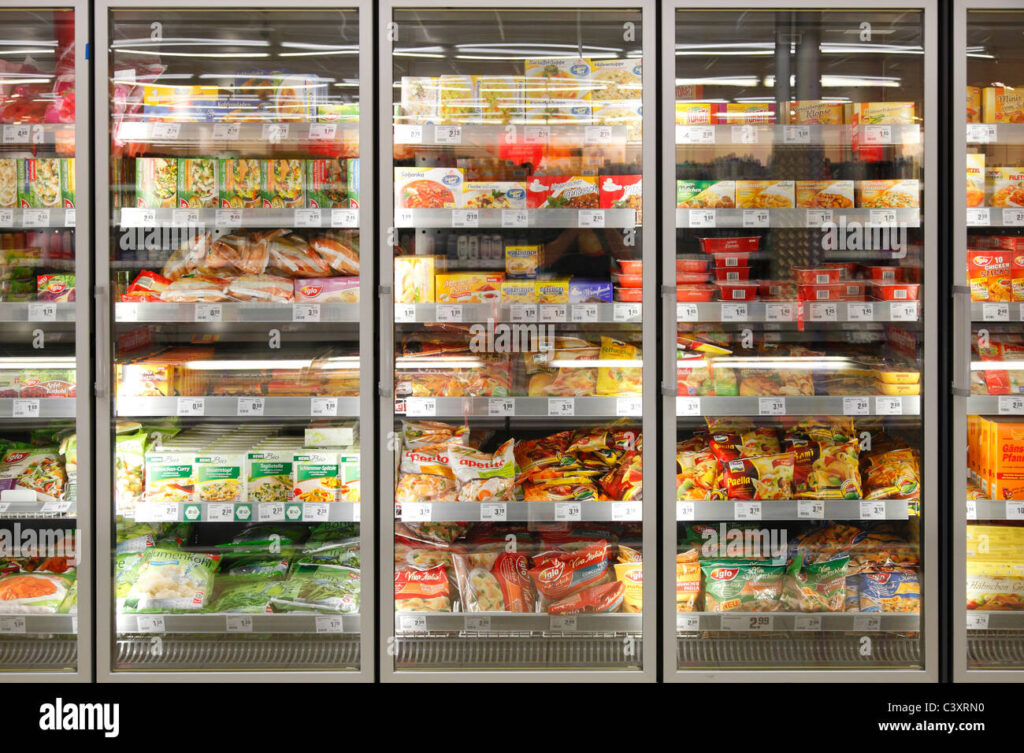

* **Supermarkets:** Supermarkets use walk-in freezers to store large quantities of frozen foods and reach-in freezers to display frozen products to customers.

* **Food Processing Plants:** Food processing plants use industrial freezers to freeze large quantities of food items for distribution.

* **Distribution Centers:** Distribution centers use large freezers to store frozen goods before they are shipped to retailers.

* **Pharmaceuticals:** Some pharmaceutical products require frozen storage to maintain their efficacy. Large freezers are used to store these products in a controlled environment.

Advantages of Using Large Freezers

* **Increased Storage Capacity:** Large freezers provide ample space to store frozen goods, reducing the need for frequent restocking.

* **Improved Inventory Management:** Large freezers make it easier to organize and manage inventory, reducing waste and spoilage.

* **Cost Savings:** By purchasing food items in bulk and storing them in a large freezer, businesses can save money on food costs.

* **Consistent Product Quality:** Proper freezer operation helps to maintain consistent product quality and prevent spoilage.

Disadvantages and Limitations of Large Freezers

* **High Initial Cost:** Large freezers can be expensive to purchase and install.

* **High Energy Consumption:** Large freezers consume a significant amount of energy, which can increase operating costs.

* **Space Requirements:** Large freezers require a significant amount of space, which may be a limiting factor for some businesses.

* **Maintenance Requirements:** Large freezers require regular maintenance to ensure optimal performance and prevent breakdowns.

Ideal User Profile for Large Freezers

Large freezers are best suited for businesses that require significant frozen storage capacity and have the space and budget to accommodate them. These businesses typically include:

* **Restaurants:** Restaurants that serve a large volume of frozen dishes.

* **Supermarkets:** Supermarkets that sell a wide variety of frozen foods.

* **Food Processing Plants:** Food processing plants that manufacture frozen food products.

* **Distribution Centers:** Distribution centers that store and distribute frozen goods.

Key Alternatives to Large Freezers

For businesses that do not require the storage capacity of a large freezer, there are several alternatives available:

* **Smaller Reach-In Freezers:** These freezers offer a more compact and affordable solution for storing smaller quantities of frozen goods.

* **Chest Freezers:** Chest freezers are a good option for storing bulky items, but they are less accessible than reach-in freezers.

Expert Overall Verdict & Recommendation

Large freezers are an essential investment for businesses that require significant frozen storage capacity. While they can be expensive to purchase and operate, they offer numerous advantages, including increased storage capacity, improved inventory management, and cost savings. Based on our analysis, we recommend carefully evaluating your specific needs and choosing a freezer that meets your requirements in terms of size, temperature control, energy efficiency, and budget. If you prioritize rapid freezing and quality preservation, a blast freezer is an excellent choice. For large-scale operations, an industrial freezer is the most suitable solution. Investing in a high-quality freezer from a reputable manufacturer and implementing a regular maintenance program will ensure the long-term performance and reliability of your freezer.

Q&A: Your Burning Questions About Large Freezers Answered

Here are some insightful questions and expert answers to address your concerns about large freezers:

1. **What’s the ideal temperature range for storing frozen food in a walk-in freezer?** The ideal temperature range is typically between -10°F (-23°C) and 0°F (-18°C). Maintaining this range ensures optimal preservation and prevents spoilage.

2. **How often should I defrost my walk-in freezer?** Defrosting frequency depends on usage and humidity levels. However, a general guideline is to defrost every 3-6 months, or when ice buildup exceeds ¼ inch.

3. **What are the key considerations for choosing a walk-in freezer door?** Consider factors such as frequency of use, space constraints, and insulation efficiency. Hinged doors are common, but sliding doors save space. Strip curtains can also help maintain temperature during frequent entry/exit.

4. **How can I improve the energy efficiency of my walk-in freezer?** Ensure proper insulation, maintain tight door seals, use energy-efficient lighting, and regularly defrost the unit. Also, consider using a door closer to prevent doors from being left open.

5. **What are the common causes of walk-in freezer breakdowns?** Common causes include compressor failure, refrigerant leaks, faulty door seals, and electrical issues. Regular maintenance can help prevent these problems.

6. **Can I convert a regular room into a walk-in freezer?** While possible, it’s not recommended without proper insulation and refrigeration expertise. Converting a room requires significant modifications to ensure temperature control and prevent moisture buildup, which can lead to structural damage.

7. **What are the benefits of using a blast freezer over a regular freezer?** Blast freezers rapidly cool food, minimizing ice crystal formation and preserving texture, flavor, and nutritional value. This results in higher-quality frozen products compared to slow freezing.

8. **How does a blast freezer work?** Blast freezers use high-velocity air to rapidly cool food items. The air is typically circulated at extremely low temperatures to quickly remove heat from the food.

9. **What type of industrial freezer is best for freezing individually quick frozen (IQF) products?** Tunnel freezers and spiral freezers are commonly used for IQF products. These freezers allow for continuous processing and ensure rapid freezing of individual food items.

10. **How can I ensure proper food safety when using a large freezer?** Maintain consistent temperatures, properly package and label food items, practice FIFO (First-In, First-Out) inventory management, and regularly clean and sanitize the freezer.

Conclusion: Mastering the World of Large Freezers

In conclusion, understanding the different types of large freezers – from walk-in models to blast freezers and industrial solutions – is crucial for businesses seeking efficient and effective cold storage. Each type offers unique advantages and is tailored to specific needs. By considering factors such as storage capacity, temperature requirements, energy efficiency, and budget, you can choose the right freezer to optimize your operations and ensure the quality of your frozen goods. Remember, proper maintenance and adherence to food safety guidelines are essential for maximizing the lifespan and performance of your large freezer. We encourage you to explore the options available, consult with refrigeration experts, and share your experiences with large freezers in the comments below. Contact our experts for a consultation on your large freezer needs to ensure you are making the best decision for your business.