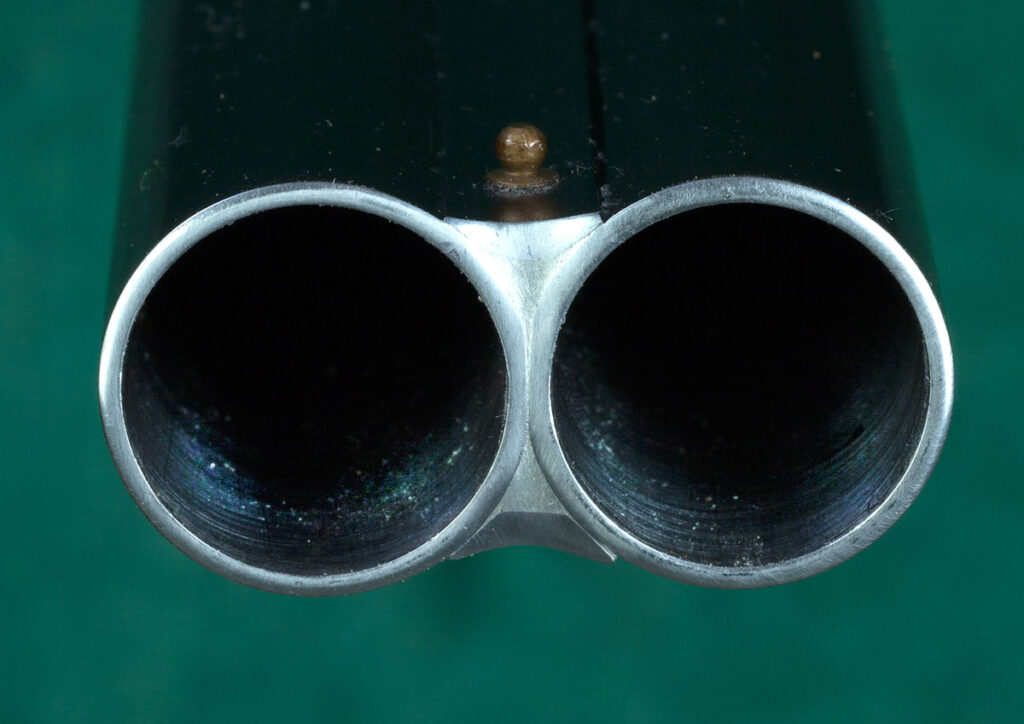

What Factors Are Considered When Choosing a Material for a Shotgun Barrel?

Selecting the right material for a shotgun barrel is a crucial decision that impacts the firearm’s performance, longevity, and safety. A shotgun barrel endures significant stress during firing, making material selection a paramount consideration. Understanding the various factors influencing this choice is essential for manufacturers and informed gun owners alike. This article will delve into the key considerations when choosing a material for a shotgun barrel, ensuring optimal performance and safety.

Strength and Durability

The primary consideration when selecting a material for a shotgun barrel is its strength and durability. The barrel must withstand the high pressures generated during firing. Shotgun cartridges can produce pressures ranging from 8,000 to over 14,000 pounds per square inch (PSI), depending on the gauge and load. Therefore, the material must possess sufficient tensile strength and yield strength to handle these pressures without deforming or failing.

Steel alloys are the most common choice due to their excellent strength-to-weight ratio and relative affordability. Different types of steel offer varying levels of strength and corrosion resistance. For instance, chrome-moly steel is often used in high-end barrels due to its superior strength and heat resistance. The heat generated during rapid firing can weaken less robust materials, making chrome-moly an ideal choice for demanding applications. [See also: Shotgun Barrel Maintenance Tips]

Corrosion Resistance

Corrosion is another significant concern, especially considering that shotgun barrels are frequently exposed to moisture, humidity, and corrosive residues from gunpowder and cleaning solvents. A material’s resistance to corrosion directly impacts the barrel’s lifespan and performance. Rust can weaken the barrel, reduce accuracy, and even lead to catastrophic failure.

Stainless steel is a popular option for shotgun barrels due to its exceptional corrosion resistance. The addition of chromium to the steel alloy creates a passive layer of chromium oxide on the surface, which protects the underlying metal from corrosion. While stainless steel is more expensive than traditional carbon steel, its enhanced corrosion resistance can justify the added cost, particularly in environments where exposure to moisture and corrosive elements is high.

Chrome lining is another method to enhance corrosion resistance. Chrome-lined barrels feature a thin layer of chromium plating on the interior surface. This plating provides a barrier against corrosion and also reduces friction, which can improve the barrel’s lifespan and ease of cleaning. However, chrome lining can sometimes slightly reduce accuracy compared to non-lined barrels.

Weight and Balance

The weight of the shotgun barrel significantly impacts the overall balance and handling of the firearm. A heavier barrel can reduce felt recoil and improve stability, while a lighter barrel can make the shotgun more maneuverable and easier to carry. The ideal weight depends on the intended use of the shotgun. For example, a hunting shotgun used for long days in the field benefits from being lightweight, whereas a target shotgun used for clay shooting may benefit from a heavier barrel for added stability.

Carbon fiber is an emerging material in shotgun barrel construction, offering a significant weight reduction compared to steel. Carbon fiber barrels typically consist of a thin steel liner wrapped in multiple layers of carbon fiber composite. This design provides the necessary strength to withstand firing pressures while significantly reducing weight. However, carbon fiber barrels are more expensive and may not be as durable as steel barrels in certain conditions.

Heat Dissipation

Heat dissipation is a critical factor, especially for shotguns used in high-volume shooting scenarios, such as sporting clays or tactical training. Repeated firing can cause the barrel to overheat, which can affect accuracy, reduce barrel life, and even pose a safety risk. Materials with good thermal conductivity can dissipate heat more efficiently, preventing excessive temperature buildup.

Steel, particularly chrome-moly steel, offers good heat dissipation properties. The steel barrel acts as a heat sink, drawing heat away from the chamber and distributing it along the barrel’s length. This helps to prevent localized overheating and maintain consistent performance. Some manufacturers also incorporate fluting or other external features to increase the surface area of the barrel, further enhancing heat dissipation.

Manufacturing Processes

The manufacturing process used to create the shotgun barrel also influences the choice of material. Some materials are easier to machine, weld, or otherwise fabricate than others. The complexity of the manufacturing process can significantly impact the cost and lead time of the barrel.

Traditional steel barrels are typically manufactured using processes such as drilling, reaming, and honing. These processes are well-established and relatively cost-effective. Advanced manufacturing techniques, such as electro-discharge machining (EDM) and laser cutting, are also used to create complex barrel designs and features. However, these techniques may be more expensive and require specialized equipment.

Cost

Cost is always a consideration when selecting a material for a shotgun barrel. The cost of the material itself, as well as the manufacturing processes required to work with it, can significantly impact the overall price of the shotgun. Manufacturers must balance performance and durability with cost-effectiveness to meet the needs of different market segments.

Carbon steel is the most affordable option, making it a popular choice for entry-level and mid-range shotguns. Stainless steel and other high-performance alloys are more expensive, but they offer enhanced durability, corrosion resistance, and performance. Exotic materials, such as titanium or carbon fiber, are typically reserved for high-end, custom-built shotguns due to their high cost and specialized manufacturing requirements. [See also: Best Budget Shotguns of the Year]

Intended Use

The intended use of the shotgun plays a crucial role in material selection. A shotgun designed for hunting waterfowl in harsh conditions requires a barrel material with excellent corrosion resistance. A shotgun used for competitive shooting requires a barrel material with high strength and heat dissipation properties. Understanding the specific demands of the application is essential for making an informed decision.

Hunting shotguns often benefit from stainless steel or chrome-lined barrels to withstand exposure to moisture and corrosive elements. Sporting shotguns may prioritize heat dissipation and balance, making chrome-moly steel or carbon fiber options attractive. Tactical shotguns require ruggedness and reliability, often favoring durable steel alloys with enhanced corrosion resistance.

Material Properties Summary

To summarize, here’s a breakdown of common materials and their key properties when used in shotgun barrels:

- Carbon Steel: Affordable, good strength, but susceptible to corrosion.

- Stainless Steel: Excellent corrosion resistance, good strength, but more expensive than carbon steel.

- Chrome-Moly Steel: High strength, good heat resistance, but can be more expensive than carbon steel.

- Carbon Fiber: Lightweight, good strength, but expensive and may not be as durable as steel in all conditions.

Conclusion

Choosing the right material for a shotgun barrel involves careful consideration of several factors, including strength, durability, corrosion resistance, weight, heat dissipation, manufacturing processes, cost, and intended use. Steel alloys remain the most common choice due to their balance of strength, affordability, and manufacturability. However, stainless steel, carbon fiber, and other advanced materials are gaining popularity in specialized applications where their unique properties offer significant advantages. By understanding these factors, manufacturers and gun owners can make informed decisions that ensure optimal performance, longevity, and safety. When choosing a material for a shotgun barrel, remember that the best choice depends on the specific needs and priorities of the user, ensuring that the shotgun barrel will perform reliably and safely for years to come. The materials chosen for a shotgun barrel are a critical component that determine how well it performs under pressure and in different environments. Consider these factors when choosing a material for a shotgun barrel to get the most out of your firearm. The strength and durability of the materials used for a shotgun barrel are the most important factors to consider. Remember to choose a material for a shotgun barrel that will last.