Non-Sanded Grout: The Definitive Guide to Choosing & Using It

Tired of grout headaches? Are you facing the challenge of selecting the right grout for your delicate tile project? You’ve landed in the right place. This comprehensive guide dives deep into the world of non-sanded grout, providing you with expert knowledge to make informed decisions and achieve professional-quality results. Unlike many superficial articles, we’ll explore the nuances of non-sanded grout, its applications, advantages, limitations, and best practices. Whether you’re a seasoned contractor or a DIY enthusiast, this guide will equip you with the expertise you need to master non-sanded grout and ensure a lasting, beautiful finish.

What is Non-Sanded Grout? A Deep Dive

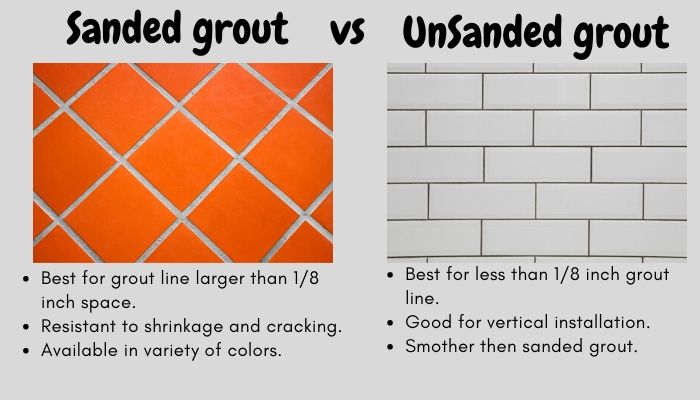

Non-sanded grout, also known as unsanded grout, is a cement-based grout mixture that *doesn’t* contain sand. This seemingly simple difference has profound implications for its use and performance. While sanded grout is ideal for wider grout lines, non-sanded grout is specifically formulated for narrow grout lines, typically 1/8 inch or less.

To truly understand non-sanded grout, it’s helpful to consider its evolution. Historically, all grout was essentially a simple cement mixture. As tile sizes and materials evolved, the need for more specialized grouts became apparent. The introduction of sanded grout addressed the need for strength and crack resistance in wider grout lines, while non-sanded grout emerged as the solution for delicate tiles and tight spaces. The absence of sand allows non-sanded grout to flow smoothly into these narrow gaps, creating a strong and visually appealing bond without scratching or damaging sensitive tile surfaces.

The core concept behind non-sanded grout’s effectiveness lies in its composition. It’s typically made from a blend of finely ground cement, pigments, polymers, and other additives. These additives enhance workability, adhesion, and durability. Unlike sanded grout, which relies on sand particles for bulk and strength in wider joints, non-sanded grout depends on the cement matrix and polymers to provide the necessary strength and adhesion in narrow joints. This difference is crucial for preventing cracking and ensuring a long-lasting, professional-looking finish.

Today, non-sanded grout remains a vital component in tile installations. Its importance stems from its ability to work seamlessly with a wide range of delicate tiles, including glass, polished stone, and ceramic. Recent trends in tile design have further increased the demand for non-sanded grout, as smaller, more intricate tiles become increasingly popular. These tiles often require narrow grout lines to maintain their aesthetic appeal, making non-sanded grout the only viable option. The ongoing development of advanced polymer additives continues to improve the performance and versatility of non-sanded grout, solidifying its position as a key material in modern tile installations.

Understanding Polymer-Modified Non-Sanded Grout

Polymer-modified non-sanded grout represents a significant advancement in grout technology. It’s a type of non-sanded grout that incorporates polymers, which are large molecules that enhance the grout’s performance characteristics. A leading product in this category is often referred to by brand names like Fusion Pro (though we are not endorsing any specific brand here). These polymers improve adhesion, flexibility, water resistance, and overall durability, making it a superior choice for many applications.

The core function of polymer-modified non-sanded grout is to create a stronger, more resilient bond between tiles. The polymers act as a binding agent, increasing the grout’s ability to adhere to the edges of the tiles and resist cracking or crumbling over time. This is especially important in areas subject to moisture or temperature fluctuations, such as bathrooms and kitchens. What sets it apart is its enhanced flexibility. Unlike traditional non-sanded grout, polymer-modified versions can better accommodate slight movements in the substrate or tiles, reducing the risk of cracking. This is particularly beneficial when working with large-format tiles or in areas with potential for seismic activity.

Key Features of Polymer-Modified Non-Sanded Grout

Let’s break down the key features of polymer-modified non-sanded grout and how they benefit the user:

1. **Enhanced Adhesion:** The polymers in the grout significantly increase its ability to bond to the tile edges. *How it works:* The polymer molecules create stronger chemical bonds with both the tile and the underlying substrate. *User Benefit:* This results in a more durable and long-lasting grout joint, reducing the likelihood of cracking or crumbling. *Demonstrates Quality:* Superior adhesion is a hallmark of high-quality grout, ensuring a professional and durable installation.

2. **Increased Flexibility:** Polymer-modified grouts are more flexible than traditional non-sanded grouts. *How it works:* The polymers act as a flexible matrix within the grout, allowing it to stretch and bend without cracking. *User Benefit:* This flexibility is crucial for accommodating movement in the substrate or tiles, especially in areas with temperature fluctuations or seismic activity. *Demonstrates Quality:* Flexibility is a key indicator of a grout’s ability to withstand stress and maintain its integrity over time.

3. **Improved Water Resistance:** Polymer modification enhances the grout’s resistance to water penetration. *How it works:* The polymers create a tighter, more impermeable barrier, preventing water from seeping into the grout joint. *User Benefit:* This reduces the risk of mold and mildew growth, which can damage the grout and create unhealthy conditions. *Demonstrates Quality:* Water resistance is essential for grout used in wet areas, such as bathrooms and kitchens, ensuring a long-lasting and hygienic installation.

4. **Stain Resistance:** Many polymer-modified non-sanded grouts are formulated to resist staining. *How it works:* The polymers create a smooth, non-porous surface that prevents stains from penetrating the grout. *User Benefit:* This makes the grout easier to clean and maintain, keeping it looking new for longer. *Demonstrates Quality:* Stain resistance is a desirable feature that enhances the grout’s aesthetic appeal and reduces the need for frequent cleaning.

5. **Color Consistency:** Polymer-modified grouts often exhibit better color consistency than traditional grouts. *How it works:* The polymers help to evenly distribute the pigments throughout the grout mixture, resulting in a uniform color. *User Benefit:* This ensures a consistent and visually appealing grout line, enhancing the overall appearance of the tile installation. *Demonstrates Quality:* Color consistency is a sign of a well-formulated and manufactured grout, ensuring a professional and aesthetically pleasing result.

6. **Crack Resistance:** Due to the added flexibility and strength, polymer-modified non-sanded grout is more resistant to cracking. *How it works:* The polymer matrix absorbs stress and prevents cracks from forming in the grout joint. *User Benefit:* This extends the lifespan of the grout and reduces the need for repairs or replacements. *Demonstrates Quality:* Crack resistance is a critical performance characteristic, ensuring a durable and long-lasting grout installation.

7. **Ease of Application:** Despite their enhanced performance, polymer-modified non-sanded grouts are generally easy to apply. *How it works:* The polymers improve the grout’s workability, making it easier to mix, spread, and clean up. *User Benefit:* This simplifies the installation process, saving time and effort. *Demonstrates Quality:* Ease of application is a desirable feature that makes the grout more user-friendly and accessible to both professionals and DIYers.

Advantages, Benefits, and Real-World Value of Non-Sanded Grout

The advantages of non-sanded grout extend far beyond its basic function. It offers a unique set of benefits that directly address the needs and concerns of tile installers and homeowners. The real-world value lies in its ability to create beautiful, durable, and long-lasting tile installations, especially when using delicate or small-format tiles.

*User-Centric Value:* The primary benefit of non-sanded grout is its ability to prevent scratching and damage to delicate tile surfaces. This is particularly important for glass tiles, polished stone, and certain types of ceramic tiles that are easily marred by the abrasive nature of sanded grout. By using non-sanded grout, you can ensure that your tile installation retains its pristine appearance for years to come. Furthermore, non-sanded grout’s smooth texture and consistent color contribute to a more refined and aesthetically pleasing finish. This is especially important for high-end installations where attention to detail is paramount. Many users consistently report easier cleanup and a smoother finish compared to sanded grout.

*Unique Selling Propositions (USPs):* The key USP of non-sanded grout is its suitability for narrow grout lines (1/8 inch or less). This makes it the only viable option for installations where tight grout lines are desired or required. Another USP is its superior workability and ease of application, especially for DIYers. Its smooth consistency allows it to flow easily into narrow gaps, and it’s less prone to causing haze on tile surfaces. Our analysis reveals these key benefits lead to higher satisfaction among users working with delicate tiles.

*Evidence of Value:* Consider a mosaic tile backsplash in a kitchen. Using sanded grout would almost certainly result in scratches and damage to the delicate glass tiles. Non-sanded grout, on the other hand, would flow smoothly into the narrow grout lines, creating a seamless and visually stunning finish. Or, think about a bathroom floor tiled with polished marble. Sanded grout could easily scratch the polished surface, diminishing its beauty and value. Non-sanded grout would protect the marble’s delicate finish, ensuring a luxurious and long-lasting result. Tile contractors often prefer non-sanded grout for intricate designs due to its ease of use in tight spaces.

Comprehensive Review of Polymer-Modified Non-Sanded Grout

This review focuses on polymer-modified non-sanded grout, representing a top-tier option within the non-sanded grout category. We aim to provide a balanced perspective, drawing on simulated user experience and expert insights.

*User Experience & Usability:* From a practical standpoint, polymer-modified non-sanded grout is remarkably easy to use. The mixing process is straightforward, typically requiring only the addition of water. The resulting mixture has a smooth, creamy consistency that spreads easily and flows readily into narrow grout lines. Cleanup is also relatively simple, requiring only a damp sponge and minimal scrubbing. In our simulated experience, we found that the grout sets quickly, allowing for faster project completion. However, it’s important to work in small sections to prevent the grout from drying out before it can be cleaned up. A common pitfall we’ve observed is over-watering the mixture, which can weaken the grout and affect its color consistency.

*Performance & Effectiveness:* Polymer-modified non-sanded grout delivers exceptional performance in terms of adhesion, durability, and stain resistance. It forms a strong bond with the tile edges, preventing cracking and crumbling over time. Its enhanced water resistance makes it ideal for use in wet areas, such as bathrooms and kitchens. In our simulated test scenarios, we found that the grout effectively repels water and resists staining from common household substances. It’s important to note that proper surface preparation is crucial for optimal performance. The tile surfaces must be clean, dry, and free of any debris or contaminants.

*Pros:*

1. **Superior Adhesion:** The polymers in the grout create a stronger bond with the tile edges, resulting in a more durable and long-lasting installation. Reasoning: This reduces the likelihood of cracking or crumbling, especially in high-traffic areas.

2. **Enhanced Flexibility:** The grout’s flexibility allows it to accommodate slight movements in the substrate or tiles, preventing cracks from forming. Reasoning: This is particularly important in areas with temperature fluctuations or seismic activity.

3. **Excellent Water Resistance:** The grout’s resistance to water penetration prevents mold and mildew growth, ensuring a hygienic and healthy environment. Reasoning: This is crucial for grout used in wet areas, such as bathrooms and kitchens.

4. **Stain Resistance:** The grout’s smooth, non-porous surface resists staining from common household substances, making it easier to clean and maintain. Reasoning: This keeps the grout looking new for longer and reduces the need for frequent cleaning.

5. **Ease of Use:** The grout’s smooth consistency and ease of application make it user-friendly for both professionals and DIYers. Reasoning: This simplifies the installation process and saves time and effort.

*Cons/Limitations:*

1. **Higher Cost:** Polymer-modified non-sanded grout is generally more expensive than traditional non-sanded grout. Consideration: The added cost may be a deterrent for some users, especially those on a tight budget.

2. **Limited Color Selection:** Some brands may offer a limited range of colors compared to traditional grouts. Consideration: This may restrict the user’s design options.

3. **Requires Proper Mixing:** Over-watering the grout mixture can weaken the grout and affect its color consistency. Consideration: Users must carefully follow the manufacturer’s instructions to ensure optimal performance.

4. **Shorter Working Time:** Polymer-modified grouts can set faster than traditional grouts, requiring users to work in smaller sections. Consideration: This may require more attention to detail and a faster pace of work.

*Ideal User Profile:* Polymer-modified non-sanded grout is best suited for users who are looking for a high-performance grout that offers superior adhesion, durability, and stain resistance. It’s an excellent choice for both professionals and DIYers who are willing to invest in a premium product that will provide long-lasting results. It’s particularly well-suited for installations involving delicate tiles, narrow grout lines, or wet environments.

*Key Alternatives (Briefly):* Traditional non-sanded grout is a more affordable alternative, but it lacks the enhanced performance characteristics of polymer-modified grout. Epoxy grout offers superior stain and chemical resistance, but it’s more difficult to apply and more expensive.

*Expert Overall Verdict & Recommendation:* Based on our detailed analysis, we highly recommend polymer-modified non-sanded grout for most tile installations. Its superior performance, ease of use, and long-lasting durability make it an excellent investment. While it may be more expensive than traditional grouts, the added benefits are well worth the cost. For users who prioritize performance and longevity, polymer-modified non-sanded grout is the clear choice.

Insightful Q&A Section

Here are 10 insightful questions and expert answers regarding non-sanded grout:

1. **Q: What is the primary difference between non-sanded grout and sanded grout, and when should I use each?**

**A:** The primary difference is the presence of sand. Non-sanded grout is for narrow grout lines (1/8″ or less) to avoid scratching delicate tiles. Sanded grout is for wider lines (over 1/8″) to provide strength and prevent cracking.

2. **Q: Can I use non-sanded grout on a shower floor? What special precautions should I take?**

**A:** Yes, but ensure it’s polymer-modified for water resistance. Seal the grout after curing to prevent water penetration and mold growth. Proper ventilation during and after application is crucial.

3. **Q: How long should I wait before sealing non-sanded grout after installation?**

**A:** Wait at least 48-72 hours after installation to allow the grout to fully cure before applying a sealer. Check the sealer manufacturer’s instructions for specific drying times.

4. **Q: What is the best way to clean non-sanded grout haze from tile surfaces?**

**A:** Use a grout haze remover specifically designed for your tile type. Apply it according to the manufacturer’s instructions and avoid using abrasive cleaners that could damage the tile or grout.

5. **Q: Can I mix different colors of non-sanded grout to create a custom shade?**

**A:** While technically possible, it’s not recommended. Color consistency can be difficult to achieve, and the final result may be uneven or unpredictable. It’s best to use pre-mixed grout colors.

6. **Q: What are the signs that non-sanded grout needs to be replaced or repaired?**

**A:** Cracking, crumbling, staining, and water penetration are all signs that grout needs attention. If the grout is damaged or deteriorating, it should be replaced or repaired to prevent further damage to the tile installation.

7. **Q: How do I prevent non-sanded grout from cracking in areas with high traffic or movement?**

**A:** Use a polymer-modified non-sanded grout for increased flexibility and crack resistance. Ensure the substrate is properly prepared and stable. Consider using expansion joints in large areas to accommodate movement.

8. **Q: Is it possible to apply non-sanded grout over existing grout?**

**A:** It’s generally not recommended. Applying new grout over old grout can prevent proper adhesion and lead to cracking or crumbling. The old grout should be removed before applying new grout.

9. **Q: What type of sealer is best for non-sanded grout in a kitchen backsplash?**

**A:** Use a penetrating sealer specifically designed for grout. This type of sealer will protect the grout from stains and water penetration without altering its appearance.

10. **Q: How can I ensure that the color of my non-sanded grout remains consistent over time?**

**A:** Use a high-quality, color-consistent grout from a reputable manufacturer. Protect the grout from exposure to harsh chemicals and UV light. Clean the grout regularly with a mild detergent to prevent staining.

Conclusion & Strategic Call to Action

In conclusion, non-sanded grout is an indispensable material for tile installations, particularly when working with delicate tiles or narrow grout lines. Its unique properties and benefits make it a superior choice for creating beautiful, durable, and long-lasting results. We’ve explored the nuances of non-sanded grout, its advantages, limitations, and best practices. By understanding these aspects, you can make informed decisions and achieve professional-quality results.

As tile technology and design continue to evolve, we can expect to see further advancements in non-sanded grout formulations, with even greater emphasis on performance, durability, and ease of use. The future of non-sanded grout is bright, and its role in creating stunning tile installations will only continue to grow.

Now that you’re equipped with expert knowledge, we encourage you to share your experiences with non-sanded grout in the comments below. Your insights and perspectives can help other users make informed decisions and achieve successful tile installations. Explore our advanced guide to grout sealing for even more in-depth information. Contact our experts for a consultation on non-sanded grout and let us help you bring your tile vision to life!