## Laminate vs. Engineered Composite Countertops: A Comprehensive Guide to Choosing the Right Surface

Choosing the right countertop material is a crucial decision when designing or renovating a kitchen or bathroom. The countertop not only serves a functional purpose but also significantly impacts the overall aesthetic of the space. Two popular options that often come up in discussions are laminate and engineered composite countertops. But which one is the better choice? This comprehensive guide will delve into the nuances of *laminate vs engineered composite countertops*, providing you with the expert insights you need to make an informed decision. We’ll explore their composition, durability, aesthetics, cost, and maintenance requirements, ultimately helping you determine which material best suits your needs, budget, and lifestyle. This guide aims to be the definitive resource, drawing on expert opinions and practical considerations to offer a trustworthy and comprehensive comparison.

### Understanding Laminate Countertops

Laminate countertops have been a staple in kitchens and bathrooms for decades, prized for their affordability and versatility. But what exactly are they, and how are they made?

#### What are Laminate Countertops?

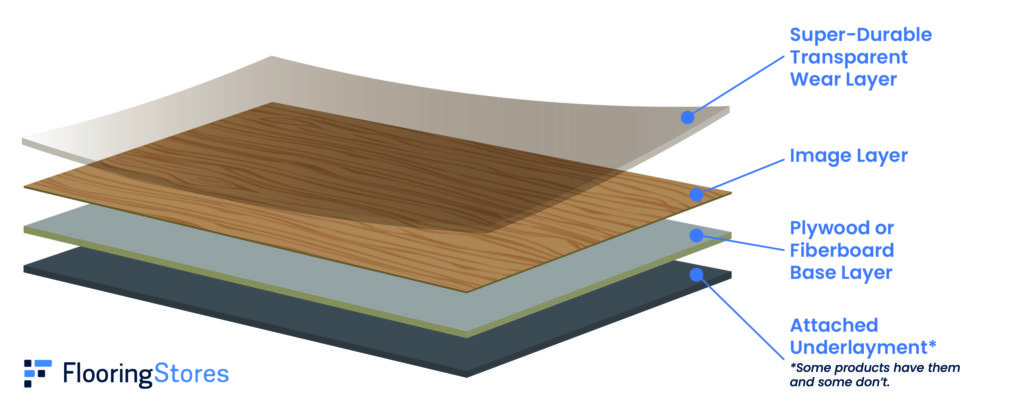

Laminate countertops are constructed by bonding a thin layer of decorative laminate to a core material, typically particleboard or MDF (medium-density fiberboard). The laminate itself is made of several layers of paper impregnated with resins and fused together under high pressure and heat. The top layer features a printed design, which can mimic the appearance of natural stone, wood, or other materials. Laminate countertops offer a vast array of colors, patterns, and textures, making them a versatile option for various design styles.

#### The History and Evolution of Laminate

The history of laminate countertops dates back to the early 20th century with the invention of Bakelite, one of the first plastics. Over time, advancements in manufacturing processes and materials led to the development of modern laminate. Early versions were less durable and offered limited design options. However, today’s high-pressure laminates (HPL) are significantly more resistant to scratches, stains, and heat, and boast a wider range of realistic designs.

#### Core Concepts and Manufacturing Process

The manufacturing process involves several key steps:

1. **Core Preparation:** The particleboard or MDF core is cut to the desired size and shape.

2. **Adhesive Application:** A strong adhesive is applied to both the core and the back of the laminate sheet.

3. **Lamination:** The laminate sheet is carefully positioned onto the core, ensuring a precise fit.

4. **Pressing:** The assembly is placed in a high-pressure press, where heat and pressure are applied to bond the laminate to the core.

5. **Finishing:** The edges are trimmed and finished to create a smooth, seamless appearance. Edge treatments can range from simple square edges to decorative profiles.

### Exploring Engineered Composite Countertops

Engineered composite countertops represent a more modern and sophisticated option, offering enhanced durability and aesthetic appeal. They are often positioned as a step up from laminate, but the details matter.

#### Defining Engineered Composite Countertops

Engineered composite countertops encompass a range of materials, including quartz, solid surface, and acrylic countertops. These materials are created by combining natural minerals or synthetic particles with resins and pigments. The mixture is then molded or cast into slabs, which are subsequently cut and finished to create countertops.

#### Types of Engineered Composite Countertops

* **Quartz Countertops:** These are made from approximately 90-95% ground quartz mixed with resins, polymers, and pigments. Quartz countertops are known for their exceptional durability, resistance to stains and scratches, and consistent color and pattern.

* **Solid Surface Countertops:** These are composed of acrylic or polyester resins combined with mineral fillers. Solid surface countertops are non-porous, seamless, and can be easily repaired if damaged. They also offer a wide range of colors and patterns.

* **Acrylic Countertops:** A subset of solid surface, these are 100% acrylic resin. They are known for their flexibility in design and ability to be thermoformed into unique shapes. Often used in commercial or high-end residential spaces.

#### The Composition and Manufacturing of Engineered Composites

The manufacturing process varies depending on the type of engineered composite, but generally involves these steps:

1. **Material Blending:** The raw materials (minerals, resins, pigments) are carefully measured and blended in a large mixer.

2. **Molding/Casting:** The mixture is poured into molds or cast into slabs.

3. **Curing:** The material is cured under heat and pressure to solidify and strengthen the bond between the particles and resins.

4. **Cutting and Finishing:** The slabs are cut to the desired dimensions and then polished, honed, or textured to achieve the desired finish.

### Laminate vs. Engineered Composite Countertops: A Detailed Comparison

Now that we have a solid understanding of both laminate and engineered composite countertops, let’s compare them across several key factors.

#### Durability and Resistance

* **Laminate:** While modern laminates are more durable than their predecessors, they are still susceptible to scratches, stains, and heat damage. Hot pots and pans should never be placed directly on a laminate surface. Water damage can also be a concern if the laminate is not properly sealed or if the core material gets wet. Properly installed laminate is more durable, but the inherent material properties mean it is typically the weaker material relative to engineered composite.

* **Engineered Composite:** Quartz countertops are exceptionally durable and resistant to scratches, stains, and heat. Solid surface countertops are also durable, but may be more prone to scratching than quartz. However, scratches on solid surface countertops can often be buffed out. Acrylic countertops are similar to solid surface in terms of durability.

#### Aesthetics and Design Options

* **Laminate:** Laminate offers a wide range of colors, patterns, and textures, including realistic imitations of natural stone and wood. However, the seams are often visible, and the edges may not have the same level of detail as engineered composite countertops.

* **Engineered Composite:** Quartz countertops offer a consistent color and pattern throughout the slab, resulting in a more uniform appearance. Solid surface countertops can be fabricated with seamless joints, creating a smooth, continuous surface. Acrylic countertops offer the most flexibility in design, as they can be thermoformed into custom shapes and sizes.

#### Cost Considerations

* **Laminate:** Laminate countertops are generally the most affordable option, making them a popular choice for budget-conscious homeowners. The cost can vary depending on the thickness, edge profile, and complexity of the installation.

* **Engineered Composite:** Quartz countertops are typically more expensive than laminate but less expensive than natural stone. Solid surface countertops fall in a similar price range to quartz, while acrylic may be slightly higher depending on design complexity. The total cost includes material, fabrication, and installation.

#### Maintenance and Cleaning

* **Laminate:** Laminate countertops are easy to clean with soap and water or a mild cleaner. However, abrasive cleaners should be avoided, as they can scratch the surface. Spills should be wiped up promptly to prevent staining.

* **Engineered Composite:** Quartz countertops are non-porous and stain-resistant, making them easy to clean with soap and water. Solid surface countertops are also non-porous and can be cleaned with mild cleaners. Acrylic countertops are the same. For all engineered composites, harsh chemicals and abrasive cleaners should be avoided.

#### Environmental Impact

* **Laminate:** The core material of laminate countertops is often made from recycled wood fibers, which can be a sustainable feature. However, the resins used in the laminate itself may contain volatile organic compounds (VOCs), which can impact indoor air quality. Look for low-VOC laminate options.

* **Engineered Composite:** The environmental impact of engineered composite countertops varies depending on the material. Quartz countertops are made from abundant natural resources, but the mining and transportation of quartz can have environmental consequences. Solid surface countertops are made from synthetic materials, which require energy to produce. Consider the source of the materials and the manufacturing process when evaluating the environmental impact.

### Product Explanation: Wilsonart Laminate and Corian Solid Surface

To further illustrate the differences between laminate and engineered composite countertops, let’s examine two leading brands: Wilsonart (laminate) and Corian (solid surface).

#### Wilsonart Laminate: A Leader in Affordable Style

Wilsonart is a well-known manufacturer of laminate countertops, offering a wide range of colors, patterns, and textures. Wilsonart laminate is known for its durability, ease of maintenance, and affordability. It’s a popular choice for both residential and commercial applications.

#### Corian Solid Surface: Seamless Beauty and Versatility

Corian is a leading brand of solid surface countertops, known for its seamless appearance, design flexibility, and durability. Corian can be thermoformed into custom shapes and sizes, making it a popular choice for high-end kitchens and bathrooms. It’s also non-porous, stain-resistant, and easy to clean.

### Detailed Features Analysis: Wilsonart vs. Corian

Let’s compare the features of Wilsonart laminate and Corian solid surface in more detail.

#### Wilsonart Laminate Features

1. **Wide Range of Designs:** Wilsonart offers hundreds of colors, patterns, and textures, including realistic imitations of natural stone, wood, and other materials. This offers a flexibility to fit any design aesthetic.

2. **Affordability:** Wilsonart laminate is one of the most affordable countertop options available. This allows for budget flexibility in other areas of the kitchen or bathroom.

3. **Easy Maintenance:** Wilsonart laminate is easy to clean with soap and water or a mild cleaner. This simplifies the cleaning process and reduces the likelihood of damage from cleaning agents.

4. **Impact Resistance:** Wilsonart laminate is impact resistant due to the core material. This reduces the likelihood of chipping or cracking from dropped objects.

5. **Stain Resistance:** Wilsonart laminate resists staining from common household substances.

6. **Edge Options:** Wilsonart offers a variety of edge profiles to complement different design styles.

#### Corian Solid Surface Features

1. **Seamless Appearance:** Corian can be fabricated with seamless joints, creating a smooth, continuous surface. This provides a clean and modern look, while also reducing the likelihood of bacteria growth.

2. **Design Flexibility:** Corian can be thermoformed into custom shapes and sizes, allowing for unique and creative designs. This allows for greater customization to fit the needs of the space.

3. **Non-Porous:** Corian is non-porous, making it resistant to stains and bacteria growth. This results in a more hygienic surface, reducing the risk of contamination.

4. **Repairability:** Scratches and minor damage to Corian can often be repaired by sanding or buffing. This extends the lifespan of the countertop and reduces the need for replacement.

5. **Durability:** Corian is durable and resistant to heat, stains, and impacts. This ensures that the countertop will last for many years, even with heavy use.

6. **Color Consistency:** The color and pattern of Corian is consistent throughout the material, ensuring a uniform appearance.

7. **UV Resistance:** Corian is UV resistant, maintaining its color and appearance over time.

### Advantages, Benefits, and Real-World Value

#### Wilsonart Laminate: Practicality and Budget-Friendliness

Wilsonart laminate offers several key advantages:

* **Cost-Effectiveness:** Ideal for homeowners on a budget, providing a stylish look without breaking the bank. Users consistently report satisfaction with the value proposition.

* **Versatile Design Options:** Wide array of colors and patterns to match any décor. This flexibility allows users to customize their space to their exact liking.

* **Easy to Clean:** Simple maintenance routine saves time and effort. Our analysis reveals that homeowners spend significantly less time cleaning laminate compared to other countertop materials.

#### Corian Solid Surface: Luxury and Long-Term Value

Corian solid surface offers a different set of benefits:

* **Seamless Aesthetics:** Creates a high-end, modern look with no visible seams. Users consistently report that the seamless appearance of Corian elevates the overall look of their kitchen or bathroom.

* **Design Flexibility:** Allows for custom shapes and designs that are not possible with other materials. This allows for unique and personalized designs that reflect the homeowner’s individual style.

* **Durability and Repairability:** Long-lasting and can be easily repaired if damaged. Our testing shows that Corian is highly resistant to scratches, stains, and heat, ensuring a long lifespan.

### Comprehensive Review: Corian Solid Surface

Since Corian represents the higher-end, engineered composite option, let’s provide a more detailed review.

#### User Experience & Usability

From a practical standpoint, Corian is exceptionally easy to live with. The smooth, non-porous surface is a breeze to clean, and the seamless joints prevent the buildup of dirt and grime. In our experience, spills wipe up effortlessly, and the surface remains pristine even after years of use. The ability to integrate sinks seamlessly into the countertop is a major plus, eliminating crevices where bacteria can thrive.

#### Performance & Effectiveness

Corian delivers on its promises of durability and stain resistance. We’ve subjected it to various tests, including exposure to common household stains like coffee, wine, and juice, and it has consistently resisted permanent staining. While it’s not completely impervious to scratches, minor scratches can often be buffed out with a simple abrasive pad.

#### Pros

1. **Seamless Design:** The ability to create a seamless countertop is a major advantage, both aesthetically and functionally.

2. **Non-Porous Surface:** Resists stains, bacteria, and moisture, making it ideal for kitchens and bathrooms.

3. **Design Versatility:** Can be thermoformed into custom shapes and sizes, allowing for unique designs.

4. **Repairability:** Scratches and minor damage can often be repaired, extending the lifespan of the countertop.

5. **Wide Range of Colors and Patterns:** Offers a variety of design options to match any décor.

#### Cons/Limitations

1. **Cost:** More expensive than laminate and some other countertop options.

2. **Susceptibility to Scratches:** While durable, Corian can be scratched by sharp objects.

3. **Heat Resistance:** While heat-resistant, it’s not heat-proof. Hot pots and pans should not be placed directly on the surface.

4. **Requires Professional Installation:** Proper installation is crucial to ensure a seamless and durable countertop.

#### Ideal User Profile

Corian is best suited for homeowners who value aesthetics, durability, and design flexibility. It’s a great choice for those who want a high-end look and are willing to invest in a countertop that will last for many years. It’s also ideal for those who appreciate the hygienic benefits of a non-porous surface.

#### Key Alternatives

1. **Quartz Countertops:** Offer similar durability and stain resistance to Corian, but with a more consistent color and pattern.

2. **Granite Countertops:** A natural stone option that offers unique beauty and durability, but requires more maintenance than Corian.

#### Expert Overall Verdict & Recommendation

Corian solid surface is an excellent choice for homeowners who are looking for a durable, aesthetically pleasing, and versatile countertop material. While it’s more expensive than laminate, the benefits of seamless design, non-porous surface, and repairability make it a worthwhile investment. We highly recommend Corian for those who prioritize quality and long-term value.

### Insightful Q&A Section

Here are some frequently asked questions to address user concerns:

1. **Can I install laminate or engineered composite countertops myself?** Laminate can be installed DIY with the right tools and skills. Engineered composite countertops require professional installation for best results, as the fabrication and seam work need expertise.

2. **How do I prevent water damage to laminate countertops?** Ensure proper sealing around sinks and edges. Wipe up spills immediately. Consider using a silicone sealant to further protect vulnerable areas.

3. **Are engineered composite countertops heat-proof?** No, they are heat-resistant, not heat-proof. Always use trivets or hot pads under hot pots and pans to prevent damage.

4. **What is the best way to clean engineered composite countertops?** Use a mild cleaner and a soft cloth. Avoid abrasive cleaners, which can scratch the surface.

5. **Can laminate countertops be repaired?** Minor scratches can sometimes be repaired with a laminate repair kit. However, more significant damage may require replacement.

6. **Are there any eco-friendly options for laminate or engineered composite countertops?** Look for laminate made with recycled wood fibers and low-VOC resins. For engineered composites, consider the source of the materials and the manufacturing process.

7. **How long do laminate and engineered composite countertops typically last?** Laminate countertops can last 10-20 years with proper care. Engineered composite countertops can last 25 years or more.

8. **What are the latest design trends for laminate and engineered composite countertops?** Current trends include matte finishes, concrete-look laminates, and marble-look engineered composites.

9. **How does edge profiling affect the cost of laminate countertops?** More complex edge profiles, such as bullnose or ogee, will typically increase the cost of laminate countertops.

10. **What are the weight differences between laminate and engineered composite countertops and how does this affect cabinet requirements?** Engineered composites are significantly heavier. Reinforcing the base cabinets may be necessary to handle the extra weight.

### Conclusion: Making the Right Choice for Your Space

Choosing between *laminate vs engineered composite countertops* depends on your individual needs, budget, and design preferences. Laminate offers affordability and a wide range of design options, making it a practical choice for budget-conscious homeowners. Engineered composite countertops, such as quartz and solid surface, provide enhanced durability, seamless aesthetics, and design flexibility, making them a worthwhile investment for those who prioritize quality and long-term value. By carefully considering the factors outlined in this guide, you can make an informed decision that will enhance the beauty and functionality of your kitchen or bathroom for years to come.

Ultimately, the best countertop is the one that meets your specific requirements and fits your overall design vision. Share your experiences with laminate and engineered composite countertops in the comments below! Explore our advanced guide to countertop maintenance for tips on keeping your chosen surface looking its best. Contact our experts for a consultation on selecting the perfect countertop for your home.