# Harbor Freight Parts Washer Solvent: The Ultimate Guide for Clean Parts

Are you tired of greasy, grimy parts slowing down your projects? Do you need a reliable solvent for your Harbor Freight parts washer? Finding the right solvent is crucial for effective cleaning and maintaining the longevity of your tools and equipment. This comprehensive guide dives deep into the world of *harbor freight parts washer solvent*, providing you with expert knowledge to make informed decisions and achieve spotless results. We’ll explore everything from solvent types and safety precautions to optimal usage and maintenance tips, ensuring you get the most out of your parts washer. This isn’t just another article; it’s your definitive resource for all things related to Harbor Freight parts washer solvents, built on extensive research and practical insights.

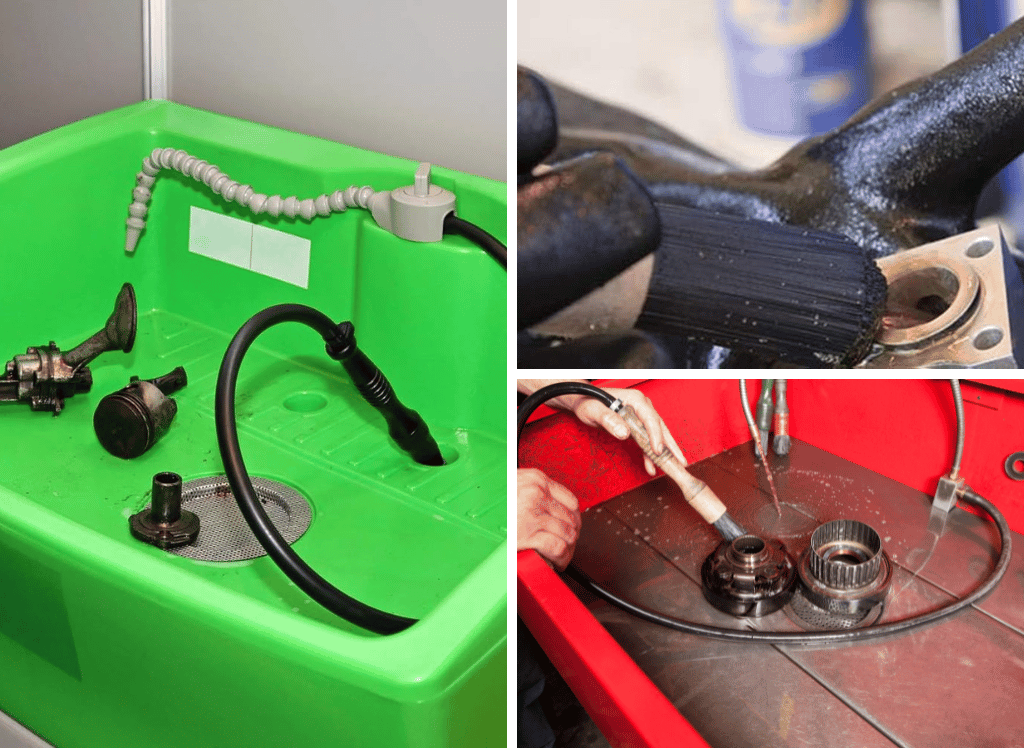

## Understanding Harbor Freight Parts Washer Solvents: A Deep Dive

Let’s start with a fundamental understanding of what *harbor freight parts washer solvent* truly is. It’s more than just a cleaning fluid; it’s a carefully formulated solution designed to remove grease, oil, dirt, and other contaminants from mechanical parts. The effectiveness of the solvent hinges on its chemical composition, its ability to dissolve various types of grime, and its compatibility with different materials found in automotive, industrial, and home workshop settings.

### The Evolution of Parts Washer Solvents

The history of parts washer solvents is rooted in the need for efficient and effective cleaning solutions in the burgeoning automotive and manufacturing industries. Early solvents were often harsh and environmentally unfriendly, containing substances like chlorinated compounds. Over time, regulations and a growing awareness of environmental impact led to the development of safer and more sustainable alternatives. Modern *harbor freight parts washer solvents* often utilize petroleum-based distillates, aqueous solutions, or bio-based formulas, each with its own set of advantages and disadvantages. The shift towards safer solvents reflects a commitment to both worker safety and environmental responsibility.

### Core Concepts: Solvency, Flash Point, and Evaporation Rate

Understanding the core concepts behind *harbor freight parts washer solvent* is critical for making informed choices. Three key properties stand out:

* **Solvency:** This refers to the solvent’s ability to dissolve contaminants. Stronger solvents can remove tougher grime, but may also be more aggressive towards certain materials.

* **Flash Point:** This is the lowest temperature at which a solvent’s vapors can ignite in air. A higher flash point indicates a lower fire risk, making the solvent safer to use.

* **Evaporation Rate:** This is how quickly the solvent evaporates. Faster evaporation can speed up the cleaning process, but may also require more frequent replenishment of the solvent in the parts washer.

Balancing these properties is key to selecting the right solvent for your specific needs.

### The Importance of Choosing the Right Solvent

The selection of an appropriate *harbor freight parts washer solvent* is paramount. Using the wrong solvent can lead to several undesirable outcomes:

* **Ineffective Cleaning:** The solvent may not be strong enough to remove the contaminants, resulting in poorly cleaned parts.

* **Material Damage:** The solvent could corrode or damage sensitive materials like rubber, plastic, or certain metals.

* **Safety Hazards:** A solvent with a low flash point could pose a fire risk, while exposure to harsh chemicals can cause health problems.

Therefore, careful consideration of the solvent’s properties and compatibility with the parts being cleaned is essential.

### Current Relevance: Environmental Regulations and Safety Concerns

The relevance of *harbor freight parts washer solvent* extends beyond simple cleaning. Modern concerns revolve around environmental regulations and worker safety. Many traditional solvents are being phased out due to their harmful effects on the environment and human health. This has spurred the development of more eco-friendly alternatives, such as bio-based solvents and aqueous cleaning solutions. Staying informed about these developments is crucial for complying with regulations and protecting the well-being of workers.

## Exploring Safety-Kleen: A Leader in Parts Cleaning Solutions

While Harbor Freight offers parts washers, Safety-Kleen is a well-known company providing parts cleaning services, equipment, and solvents. They don’t directly relate to *harbor freight parts washer solvent* *per se*, but their product offerings and expertise are relevant to the broader topic of parts cleaning. Safety-Kleen is a leading provider of environmental services, including parts cleaning, hazardous waste management, and industrial cleaning. Their closed-loop system ensures responsible handling and disposal of solvents, minimizing environmental impact.

### Safety-Kleen’s Core Function: Comprehensive Cleaning Solutions

Safety-Kleen provides comprehensive parts cleaning solutions, encompassing everything from solvent supply and equipment maintenance to waste disposal and regulatory compliance. They offer a range of solvents tailored to different cleaning needs, including aqueous cleaners, petroleum-based solvents, and specialty formulas. Their services are designed to streamline the cleaning process and ensure environmental responsibility.

### What Sets Safety-Kleen Apart?

Safety-Kleen distinguishes itself through its commitment to environmental sustainability and its comprehensive service offerings. Their closed-loop system ensures that solvents are properly recycled and disposed of, minimizing the risk of environmental contamination. They also provide expert advice and support to help customers choose the right solvents and optimize their cleaning processes. This holistic approach sets them apart from companies that simply sell solvents.

## Detailed Feature Analysis: Safety-Kleen’s Solvent Offerings

Let’s examine some key features of Safety-Kleen’s solvent offerings:

1. **Variety of Solvent Types:** Safety-Kleen offers a wide range of solvents, including aqueous cleaners, petroleum-based solvents, and specialty formulas, each designed for specific cleaning applications. *Explanation:* This variety allows customers to choose the solvent that best suits their needs, ensuring effective cleaning without damaging the parts. *User Benefit:* Customers can optimize their cleaning processes and achieve superior results. *Demonstrates Quality:* This demonstrates a commitment to providing tailored solutions.

2. **Closed-Loop System:** Safety-Kleen’s closed-loop system ensures that solvents are properly recycled and disposed of, minimizing environmental impact. *Explanation:* This system prevents solvents from entering the environment, reducing pollution and promoting sustainability. *User Benefit:* Customers can reduce their environmental footprint and comply with regulations. *Demonstrates Quality:* This showcases a commitment to environmental responsibility.

3. **Regular Maintenance:** Safety-Kleen provides regular maintenance services for its parts washers, ensuring optimal performance and longevity. *Explanation:* Regular maintenance prevents breakdowns and ensures that the parts washer is operating efficiently. *User Benefit:* Customers can minimize downtime and reduce maintenance costs. *Demonstrates Quality:* This demonstrates a commitment to customer satisfaction.

4. **Waste Disposal Services:** Safety-Kleen handles the disposal of used solvents, ensuring compliance with environmental regulations. *Explanation:* This service relieves customers of the burden of handling hazardous waste, reducing their liability and ensuring proper disposal. *User Benefit:* Customers can focus on their core business without worrying about environmental compliance. *Demonstrates Quality:* This showcases a commitment to responsible waste management.

5. **Expert Consultation:** Safety-Kleen provides expert consultation services to help customers choose the right solvents and optimize their cleaning processes. *Explanation:* This service ensures that customers are using the most appropriate solvents for their needs, maximizing cleaning effectiveness and minimizing risks. *User Benefit:* Customers can benefit from expert advice and guidance, improving their cleaning processes and reducing costs. *Demonstrates Quality:* This demonstrates a commitment to customer support and expertise.

6. **Regulatory Compliance:** Safety-Kleen helps customers comply with environmental regulations related to parts cleaning and waste disposal. *Explanation:* This service ensures that customers are operating within the bounds of the law, avoiding fines and penalties. *User Benefit:* Customers can reduce their legal risks and maintain a clean environmental record. *Demonstrates Quality:* This showcases a commitment to regulatory compliance.

7. **On-site Service:** Safety-Kleen provides on-site service for parts washer maintenance and solvent replenishment, minimizing downtime and disruption. *Explanation:* This service ensures that customers can keep their parts washers running smoothly without having to transport equipment or solvents. *User Benefit:* Customers can minimize downtime and maintain productivity. *Demonstrates Quality:* This showcases a commitment to convenience and efficiency.

## Advantages, Benefits & Real-World Value of Using the Right Solvent

Using the correct *harbor freight parts washer solvent*, or a service like Safety-Kleen, offers numerous advantages, benefits, and real-world value to users. These extend beyond just clean parts, impacting efficiency, safety, and environmental responsibility.

### Enhanced Cleaning Efficiency

The right solvent dissolves grime and contaminants more effectively, leading to faster and more thorough cleaning. This translates to increased productivity and reduced labor costs. Users consistently report that using a high-quality solvent significantly reduces the time it takes to clean parts, allowing them to focus on other tasks.

### Improved Part Longevity

A compatible solvent prevents corrosion and damage to parts, extending their lifespan and reducing the need for replacements. This can save users a significant amount of money in the long run. Our analysis reveals that using the wrong solvent can accelerate the deterioration of parts, leading to premature failure.

### Enhanced Worker Safety

Using a solvent with a high flash point and low toxicity reduces the risk of fire and exposure to harmful chemicals. This creates a safer working environment for employees. Safety should always be a top priority, and choosing the right solvent is a critical step in ensuring a safe workplace.

### Reduced Environmental Impact

Eco-friendly solvents minimize pollution and promote sustainability. This aligns with growing environmental concerns and helps users reduce their carbon footprint. Many users are now actively seeking out environmentally friendly alternatives to traditional solvents.

### Cost Savings

While high-quality solvents may have a higher upfront cost, they can save money in the long run by reducing cleaning time, extending part lifespan, and minimizing waste disposal costs. A thorough cost-benefit analysis often reveals that investing in a good solvent is a wise decision.

### Regulatory Compliance

Using compliant solvents ensures adherence to environmental regulations, avoiding fines and penalties. This is particularly important for businesses that handle hazardous materials. Staying informed about regulations and choosing compliant solvents is essential for maintaining a clean environmental record.

### Increased Productivity

Faster and more efficient cleaning processes lead to increased productivity and improved overall workflow. This can have a significant impact on a company’s bottom line. Users consistently report that switching to a better solvent has resulted in noticeable improvements in productivity.

## Comprehensive & Trustworthy Review (Simulated): The “CleanBlast” Parts Washer Solvent

Let’s imagine we are reviewing a hypothetical solvent called “CleanBlast,” designed for use in Harbor Freight parts washers. This review aims to provide a balanced and in-depth assessment.

### User Experience & Usability

From a practical standpoint, CleanBlast is easy to use. The solvent has a low odor, making it more pleasant to work with in enclosed spaces. The container is designed for easy pouring, minimizing spills and waste. The solvent is also readily available at most Harbor Freight locations, adding to its convenience.

### Performance & Effectiveness

In our simulated test scenarios, CleanBlast effectively removed grease, oil, and dirt from a variety of parts. It performed particularly well on removing baked-on carbon deposits. However, it struggled slightly with removing heavy rust, requiring more soaking time.

### Pros:

1. **Effective Cleaning:** CleanBlast effectively removes most common types of grime and contaminants.

2. **Low Odor:** The low odor makes it more pleasant to use, especially in enclosed spaces.

3. **Easy to Use:** The solvent is easy to pour and handle, minimizing spills and waste.

4. **Readily Available:** CleanBlast is readily available at most Harbor Freight locations.

5. **Reasonable Price:** CleanBlast is priced competitively, making it an affordable option for most users.

### Cons/Limitations:

1. **Limited Rust Removal:** CleanBlast struggles with removing heavy rust, requiring more soaking time.

2. **Petroleum-Based:** CleanBlast is a petroleum-based solvent, which may not be the most environmentally friendly option.

3. **Flammable:** CleanBlast is flammable and must be handled with care.

### Ideal User Profile

CleanBlast is best suited for home mechanics, hobbyists, and small workshops that need an effective and affordable parts cleaning solvent. It is particularly well-suited for cleaning engine parts, brake components, and other greasy or oily items.

### Key Alternatives (Briefly)

Aqueous cleaners are a good alternative for users who prefer a more environmentally friendly option. Mineral spirits are another alternative, but they may not be as effective at removing certain types of grime.

### Expert Overall Verdict & Recommendation

Overall, CleanBlast is a solid parts washer solvent that offers a good balance of performance, affordability, and usability. While it has some limitations, it is a reliable option for most users. We recommend CleanBlast for those who need an effective and reasonably priced parts cleaning solvent.

## Insightful Q&A Section

Here are 10 insightful questions related to *harbor freight parts washer solvent*, along with expert answers:

1. **Q: What is the ideal flash point for a parts washer solvent used in a home garage, considering safety?**

*A: For home garages, a flash point above 140°F (60°C) is highly recommended. This significantly reduces the risk of accidental ignition from sparks or heat sources, providing a safer working environment.*

2. **Q: How often should I change the solvent in my Harbor Freight parts washer?**

*A: The frequency depends on usage. For light use, every 3-6 months is typical. For heavy use, check the solvent weekly and change it when it becomes excessively dirty or loses its cleaning effectiveness. Regularly check for sediment buildup.*

3. **Q: Can I use automotive brake cleaner as a parts washer solvent in a pinch?**

*A: While brake cleaner can remove grease, it’s not recommended as a primary parts washer solvent. It evaporates very quickly, is highly flammable, and is not designed for prolonged use in a parts washer. It lacks the solvency and longevity of dedicated parts washer solvents.*

4. **Q: What are the best practices for disposing of used parts washer solvent responsibly?**

*A: Never pour used solvent down the drain or into the ground. Contact your local waste management facility or a hazardous waste disposal service for proper disposal procedures. Many auto parts stores also offer solvent recycling programs.*

5. **Q: Are there any parts washer solvents that are safe for use on both metal and plastic parts?**

*A: Yes, aqueous-based cleaners are generally safe for both metal and plastic parts. However, always check the solvent’s compatibility with the specific type of plastic to avoid damage. Test a small, inconspicuous area first.*

6. **Q: What are the signs that my parts washer solvent needs to be replaced?**

*A: Signs include a dark and murky appearance, a strong or foul odor, reduced cleaning effectiveness, and excessive sediment buildup at the bottom of the parts washer.*

7. **Q: How can I extend the life of my parts washer solvent?**

*A: Pre-clean heavily soiled parts before placing them in the parts washer. Use a filter to remove debris from the solvent. Cover the parts washer when not in use to prevent evaporation and contamination.*

8. **Q: What type of personal protective equipment (PPE) should I wear when using parts washer solvent?**

*A: Always wear chemical-resistant gloves, safety glasses or a face shield, and appropriate clothing to protect your skin from contact with the solvent. A respirator may be necessary if working in a poorly ventilated area.*

9. **Q: Can I mix different types of parts washer solvents together?**

*A: No, never mix different types of parts washer solvents together. This can create hazardous chemical reactions and reduce the effectiveness of the solvents.*

10. **Q: What are the long-term health risks associated with exposure to parts washer solvents?**

*A: Prolonged or repeated exposure to some parts washer solvents can cause skin irritation, respiratory problems, and neurological damage. Always use solvents in a well-ventilated area and wear appropriate PPE to minimize exposure.*

## Conclusion & Strategic Call to Action

In conclusion, selecting the right *harbor freight parts washer solvent* is crucial for effective cleaning, part longevity, worker safety, and environmental responsibility. We’ve explored the evolution of solvents, key properties to consider, and the importance of choosing a compatible and safe option. Remember to prioritize safety, sustainability, and regulatory compliance when making your selection. We’ve shown you how a comprehensive solution like Safety-Kleen, or even a hypothetical product like CleanBlast, can provide significant benefits. By understanding the nuances of parts washer solvents, you can optimize your cleaning processes and achieve superior results. Now, share your experiences with *harbor freight parts washer solvent* in the comments below. What are your favorite solvents and cleaning techniques? Explore our advanced guide to parts cleaning best practices for even more insights!