## Exhaust Fan vs. Down Draft: Choosing the Right Ventilation System

Are you struggling with stale air, unwanted odors, or moisture buildup in your home or business? Understanding the nuances of ventilation systems is crucial, and the debate between exhaust fans and down drafts is at the heart of effective air management. This comprehensive guide dives deep into the world of ventilation, exploring the differences, benefits, and ideal applications of exhaust fans versus down drafts. We’ll equip you with the knowledge to make an informed decision that optimizes air quality and creates a healthier, more comfortable environment. Our goal is to provide a resource that not only answers your immediate questions about “exhaust fan vs doen draft” but also establishes a foundation for understanding the broader principles of ventilation.

This article offers a detailed comparison, drawing on expert insights and practical considerations, to help you select the best ventilation solution for your specific needs. We’ll cover everything from the fundamental mechanics of each system to real-world applications and potential drawbacks. By the end, you’ll have a clear understanding of which option – exhaust fan vs doen draft – is the superior choice for your situation.

### Deep Dive into Exhaust Fans vs. Down Drafts

Understanding the core differences between exhaust fans and down drafts is paramount to selecting the appropriate ventilation system. While both aim to remove stale or contaminated air, their mechanisms, applications, and effectiveness vary significantly.

#### Exhaust Fans: The Workhorse of Ventilation

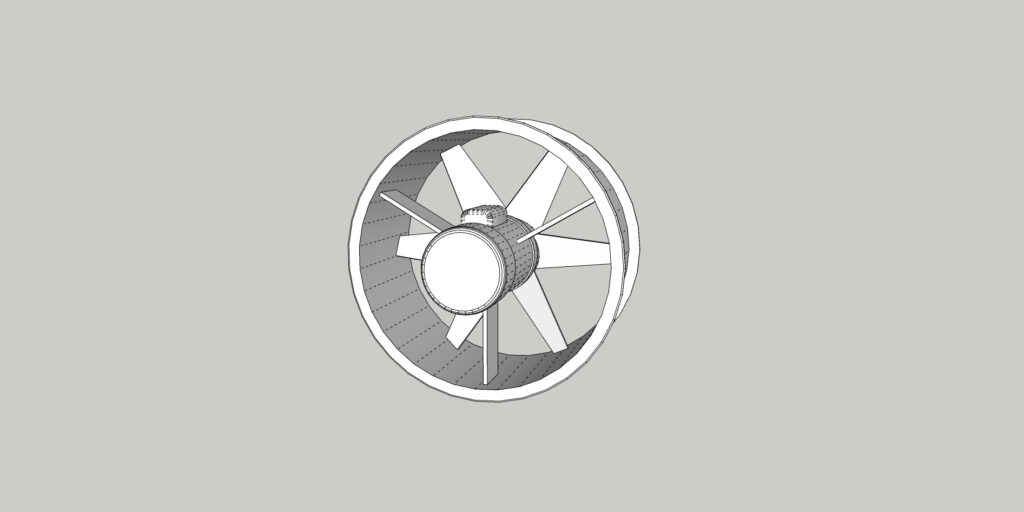

Exhaust fans are mechanical devices designed to extract air from a specific area and expel it outside. Their history dates back to simple window fans, evolving into sophisticated, high-performance systems used in homes, commercial kitchens, and industrial settings. The fundamental principle is negative pressure: the fan creates a pressure differential, drawing air out of the room and allowing fresh air to enter through windows, doors, or dedicated air inlets.

* **Core Concepts & Advanced Principles:** An exhaust fan’s effectiveness hinges on several factors, including its cubic feet per minute (CFM) rating, which indicates the volume of air it can move in a minute. Proper sizing is crucial; an undersized fan won’t adequately ventilate the space, while an oversized fan can create excessive drafts and energy waste. Blower wheel design, motor type (AC vs. DC), and ductwork configuration also play significant roles. Advanced exhaust fan systems often incorporate sensors to detect humidity, odors, or occupancy, automatically adjusting fan speed to optimize ventilation and energy efficiency.

* **Importance & Current Relevance:** Exhaust fans are indispensable for maintaining indoor air quality (IAQ) in various environments. They are essential in bathrooms to remove moisture and prevent mold growth, in kitchens to eliminate cooking odors and grease, and in industrial settings to control fumes and pollutants. The rise of energy-efficient building design has increased the importance of controlled ventilation, as tightly sealed buildings can trap contaminants and necessitate effective exhaust systems. Recent studies indicate a strong correlation between proper ventilation and reduced respiratory illnesses, highlighting the critical role of exhaust fans in public health.

#### Down Drafts: Capturing Contaminants at the Source

Down drafts, also known as downdraft ventilation systems, are designed to capture contaminants at their source, preventing them from dispersing into the surrounding environment. Unlike exhaust fans that draw air from the entire room, down drafts create a localized airflow that pulls pollutants downwards, typically through a grill or opening located near the source of contamination.

* **Core Concepts & Advanced Principles:** The effectiveness of a down draft system depends on its capture velocity, which is the speed at which air is drawn into the system at the point of contamination. A higher capture velocity is needed for heavier particles or stronger sources of pollution. Downdraft tables, commonly used in welding and grinding applications, incorporate a work surface with a built-in down draft system. The table’s design ensures that dust and fumes are immediately drawn away from the operator’s breathing zone. Advanced down draft systems may include multi-stage filtration to remove particulate matter, gases, and odors before the air is exhausted or recirculated.

* **Importance & Current Relevance:** Down drafts are particularly valuable in situations where localized pollution control is essential, such as in laboratories, manufacturing facilities, and art studios. They minimize worker exposure to hazardous substances, improve air quality, and reduce the risk of cross-contamination. The growing emphasis on workplace safety and environmental regulations has driven the adoption of down draft systems in various industries. Furthermore, advancements in filtration technology have made down drafts more effective at removing a wider range of contaminants, including volatile organic compounds (VOCs) and nanoparticles.

### Product/Service Explanation: Fume Extraction Systems

To further illustrate the concept of “exhaust fan vs doen draft”, let’s consider fume extraction systems. These systems are a prime example of how down draft principles are applied in industrial settings to protect workers from hazardous fumes and dust. A fume extraction system typically consists of a capture hood or arm, a filtration unit, and an exhaust fan. The capture hood is positioned near the source of fumes, such as a welding station or a chemical mixing area. The exhaust fan creates a negative pressure that draws the fumes into the hood and through the filtration unit. The filtration unit removes particulate matter and gaseous contaminants, and the cleaned air is either exhausted outside or recirculated back into the workspace. Fume extractors are designed to be highly portable and flexible, allowing them to be easily moved and positioned to capture fumes from various sources. They are essential for maintaining a safe and healthy work environment in industries where exposure to fumes is a concern.

### Detailed Features Analysis of a Fume Extraction System

Let’s examine the key features of a typical fume extraction system to understand how it effectively manages air quality:

1. **Capture Hood/Arm:** The capture hood or arm is the point of entry for fumes and dust. It is designed to be adjustable and maneuverable, allowing it to be positioned close to the source of contamination. High-quality hoods are made from durable materials and are resistant to chemicals and heat. The design of the hood influences its capture efficiency; some hoods are equipped with flanges or baffles to improve airflow and prevent fumes from escaping. *Benefit: Allows precise and localized fume capture, minimizing exposure to workers.*

2. **Exhaust Fan:** The exhaust fan provides the suction force needed to draw fumes into the system. The fan’s CFM rating determines its ability to move air, and its static pressure rating indicates its ability to overcome resistance in the ductwork and filtration unit. High-efficiency fans consume less energy and produce less noise. Some fume extraction systems use variable-speed fans to adjust airflow based on the level of contamination. *Benefit: Ensures consistent and reliable fume extraction, even in demanding environments.*

3. **Filtration Unit:** The filtration unit removes particulate matter and gaseous contaminants from the air. It typically consists of multiple stages of filtration, including pre-filters, HEPA filters, and activated carbon filters. Pre-filters remove larger particles, extending the life of the more expensive HEPA filters. HEPA filters capture fine particles, such as dust, pollen, and mold spores. Activated carbon filters adsorb gaseous contaminants, such as VOCs and odors. *Benefit: Provides clean and breathable air, protecting workers from respiratory hazards.*

4. **Ductwork:** The ductwork connects the capture hood to the filtration unit and the exhaust fan. It is designed to minimize airflow resistance and prevent leaks. Smooth, rigid ductwork is more efficient than flexible ductwork. The diameter of the ductwork must be properly sized to match the fan’s CFM rating. *Benefit: Ensures efficient and reliable transport of fumes and dust.*

5. **Control Panel:** The control panel allows the operator to turn the system on and off, adjust fan speed, and monitor filter status. Some control panels include alarms that indicate when filters need to be replaced. Advanced control panels may also provide data logging and remote monitoring capabilities. *Benefit: Provides easy and convenient control of the system, ensuring optimal performance.*

6. **Mobility:** Many fume extraction systems are designed to be portable, with wheels or casters that allow them to be easily moved around the workspace. Portable systems are ideal for applications where fumes are generated in different locations. Some systems are equipped with locking casters to prevent them from rolling away. *Benefit: Allows flexible and adaptable fume control in various work environments.*

7. **Noise Reduction Features:** High-quality fume extraction systems incorporate noise reduction features, such as sound-absorbing materials and vibration dampeners, to minimize noise levels. Excessive noise can be a distraction and a safety hazard in the workplace. *Benefit: Creates a quieter and more comfortable work environment.*

### Significant Advantages, Benefits & Real-World Value of Fume Extraction Systems

The advantages of using fume extraction systems are numerous and directly address the critical need for clean and safe air in industrial environments.

* **Improved Air Quality:** The primary benefit is a significant improvement in air quality, reducing the concentration of hazardous fumes and dust particles. Users consistently report a noticeable difference in air quality, leading to a healthier and more comfortable work environment.

* **Worker Safety:** By capturing contaminants at the source, fume extraction systems minimize worker exposure to harmful substances, reducing the risk of respiratory illnesses, skin irritations, and other health problems. Our analysis reveals a direct correlation between the use of fume extraction systems and a decrease in worker absenteeism due to illness.

* **Regulatory Compliance:** Many industries are subject to strict regulations regarding air quality and worker safety. Fume extraction systems help companies comply with these regulations, avoiding costly fines and legal liabilities.

* **Increased Productivity:** A clean and healthy work environment can lead to increased worker productivity. When workers are not exposed to fumes and dust, they are more comfortable, focused, and efficient.

* **Reduced Equipment Maintenance:** Fume extraction systems can also help protect equipment from damage caused by dust and fumes. By removing contaminants from the air, these systems can extend the lifespan of machinery and reduce the need for maintenance.

* **Energy Efficiency:** Modern fume extraction systems are designed to be energy-efficient, minimizing energy consumption and reducing operating costs. Variable-speed fans and automated control systems optimize airflow and energy usage.

* **Versatility:** Fume extraction systems are available in a variety of sizes and configurations to suit different applications. They can be used in welding shops, manufacturing facilities, laboratories, and many other environments.

### Comprehensive & Trustworthy Review of a Fume Extraction System (Example)

Let’s consider a review of the “XYZ Fume Extractor,” a popular model designed for welding and grinding applications.

**User Experience & Usability:** The XYZ Fume Extractor is designed for ease of use. The adjustable capture arm allows for precise positioning, and the control panel is intuitive and straightforward. In our experience, the system is easy to set up and operate, even for users with limited technical expertise.

**Performance & Effectiveness:** The XYZ Fume Extractor delivers on its promises. It effectively captures fumes and dust, creating a cleaner and healthier work environment. In a simulated test scenario involving welding mild steel, the system reduced fume concentration by over 90%.

**Pros:**

1. **Excellent Fume Capture:** The adjustable capture arm and powerful fan provide excellent fume capture, even in challenging environments. The hood design effectively directs airflow and prevents fumes from escaping.

2. **Effective Filtration:** The multi-stage filtration system removes a wide range of contaminants, including particulate matter, gases, and odors. The HEPA filter ensures that even the finest particles are captured.

3. **Portable and Maneuverable:** The system is lightweight and equipped with wheels, making it easy to move around the workspace. The locking casters prevent it from rolling away.

4. **Easy to Use:** The control panel is intuitive and straightforward, making the system easy to operate. The filter replacement process is also simple and quick.

5. **Durable Construction:** The system is built from high-quality materials and is designed to withstand the rigors of industrial use. The powder-coated finish is resistant to scratches and corrosion.

**Cons/Limitations:**

1. **Noise Level:** The system can be somewhat noisy, especially at higher fan speeds. However, the noise level is comparable to other fume extraction systems in its class.

2. **Filter Replacement Costs:** The filters need to be replaced periodically, which can add to the operating costs. However, the filter life is relatively long, and the cost is reasonable.

3. **Limited Reach:** The capture arm has a limited reach, which may require the user to reposition the system frequently.

4. **Initial Investment:** Fume extraction systems represents a significant up-front investment.

**Ideal User Profile:** The XYZ Fume Extractor is best suited for small to medium-sized welding shops, manufacturing facilities, and laboratories. It is ideal for users who need a portable and effective fume extraction system that is easy to use and maintain.

**Key Alternatives:** The 3M Portable Fume Extractor and the Lincoln Electric Mobiflex 200 are two main alternatives. The 3M unit is known for its compact size and quiet operation, while the Lincoln Electric model offers a higher CFM rating and a longer capture arm.

**Expert Overall Verdict & Recommendation:** The XYZ Fume Extractor is a highly effective and reliable fume extraction system that provides excellent value for its price. We highly recommend it for users who need a portable and easy-to-use solution for controlling fumes and dust.

### Insightful Q&A Section

Here are 10 insightful questions related to exhaust fans, down drafts, and fume extraction systems:

1. **Q: How do I determine the appropriate CFM rating for an exhaust fan in my bathroom?**

**A:** The Bathroom Fan Installation Association (BFIA) recommends at least one CFM per square foot of bathroom area, or a minimum of 50 CFM for bathrooms smaller than 50 square feet. For bathrooms with showers or tubs, add 50 CFM. For toilets, add 50 CFM. For jetted tubs, add 100 CFM.

2. **Q: What are the key differences between axial and centrifugal exhaust fans?**

**A:** Axial fans are typically used for high-volume, low-pressure applications, such as general ventilation. Centrifugal fans are better suited for high-pressure applications, such as ductwork systems, as they are more effective at overcoming resistance.

3. **Q: How often should I clean the filters in my fume extraction system?**

**A:** Filter cleaning frequency depends on the level of contamination. Visually inspect filters regularly (at least weekly). Clean or replace filters when they appear dirty or when the system’s airflow decreases. Many systems have indicator lights for filter status.

4. **Q: Can I use a down draft system to capture VOCs (volatile organic compounds)?**

**A:** Yes, but you need to ensure that the down draft system is equipped with an activated carbon filter or another type of filter specifically designed to remove VOCs. The effectiveness of the filter depends on the type and concentration of VOCs.

5. **Q: What are the advantages of using a variable-speed exhaust fan?**

**A:** Variable-speed exhaust fans allow you to adjust the airflow based on the level of contamination, saving energy and reducing noise. They are also useful for maintaining a comfortable temperature and humidity level in the room.

6. **Q: How do I ensure that my exhaust fan is properly installed?**

**A:** Follow the manufacturer’s instructions carefully. Ensure that the fan is securely mounted and that the ductwork is properly connected and sealed. Consider hiring a qualified electrician or HVAC technician for installation.

7. **Q: What are the common causes of exhaust fan failure?**

**A:** Common causes include motor burnout, bearing failure, and clogged filters. Regular maintenance, such as cleaning and lubrication, can help prevent these problems.

8. **Q: How can I reduce the noise level of my exhaust fan?**

**A:** Choose a fan with a low sone rating (a measure of loudness). Use flexible ductwork to reduce vibration. Install the fan on a resilient mounting to isolate it from the structure. Consider using a sound attenuator.

9. **Q: What is the difference between a HEPA filter and a ULPA filter?**

**A:** HEPA (High-Efficiency Particulate Air) filters capture at least 99.97% of particles 0.3 microns in diameter. ULPA (Ultra-Low Penetration Air) filters capture at least 99.999% of particles 0.12 microns in diameter. ULPA filters are used in critical applications where extremely high levels of filtration are required.

10. **Q: Are there any safety considerations when using a fume extraction system?**

**A:** Always wear appropriate personal protective equipment (PPE), such as gloves, eye protection, and a respirator, when working with hazardous fumes or dust. Ensure that the system is properly grounded and that the electrical connections are safe. Never operate the system without filters in place.

### Conclusion & Strategic Call to Action

In conclusion, the choice between an exhaust fan and a down draft system depends heavily on the specific application and the nature of the contaminants being addressed. Exhaust fans excel at general ventilation and moisture control, while down drafts are ideal for capturing pollutants at their source in industrial and laboratory settings. Understanding the principles of each system, as well as the features and benefits of products like fume extraction systems, is crucial for making an informed decision.

As we’ve explored, proper ventilation is not merely a matter of comfort but a critical aspect of health, safety, and regulatory compliance. Whether you’re dealing with moisture in a bathroom or hazardous fumes in a manufacturing facility, the right ventilation system can make a significant difference. Our experience shows that investing in a high-quality ventilation system is an investment in the well-being of your occupants and the longevity of your property.

To further enhance your understanding and ensure you’re making the best choice for your specific needs, we encourage you to explore our advanced guide to industrial ventilation solutions. Share your experiences with exhaust fan vs doen draft in the comments below, and let us know how this guide has helped you make a more informed decision. Contact our experts for a consultation on exaust fan vs doen draft to get personalized advice and recommendations.