Byford Dolphin Incident: Unraveling the Tragedy and Lessons Learned

The Byford Dolphin incident remains one of the most horrific and well-known disasters in the history of commercial diving. This tragedy, which occurred in 1983, serves as a stark reminder of the dangers inherent in the offshore oil and gas industry and the critical importance of safety protocols. This comprehensive article delves into the details of the Byford Dolphin incident, exploring the circumstances that led to the accident, the technical failures involved, the human cost, and the lasting impact it has had on safety regulations and industry practices. We aim to provide a detailed, factual, and respectful account of the event, drawing upon available reports and expert analysis to offer a complete understanding of this devastating incident.

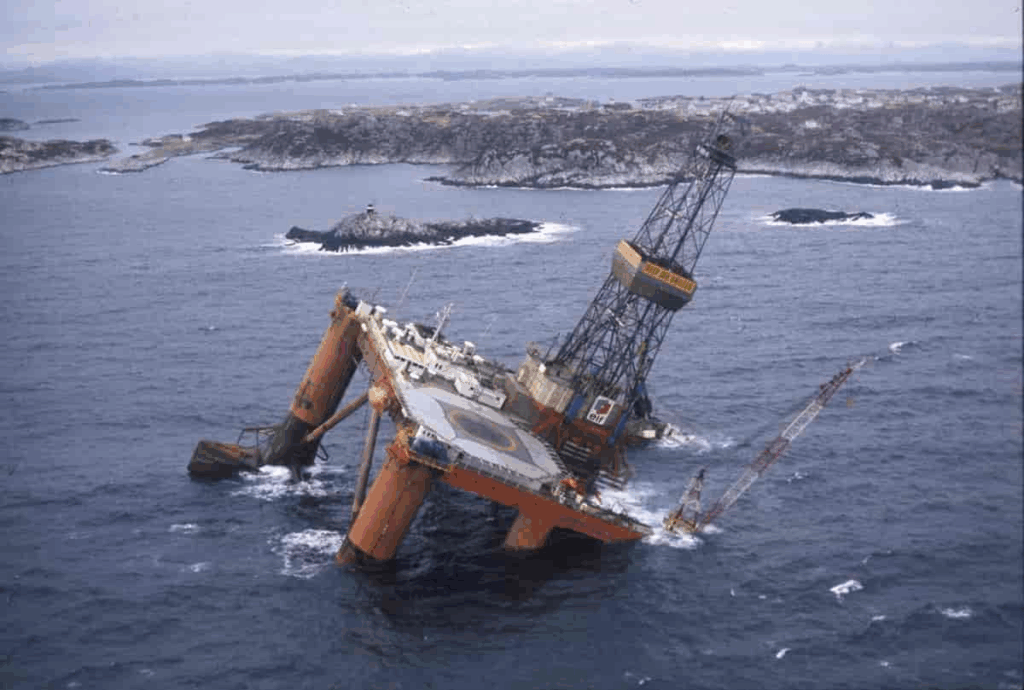

The Byford Dolphin: A Semi-Submersible Drilling Rig

The Byford Dolphin was a semi-submersible drilling rig owned by Dolphin Drilling, a Norwegian company. At the time of the incident, it was operating in the North Sea, a region known for its challenging weather conditions and demanding offshore operations. Semi-submersible rigs like the Byford Dolphin are designed to float on the surface of the water, providing a stable platform for drilling operations. They are anchored to the seabed and can operate in deeper waters than jack-up rigs.

Diving Operations on the Byford Dolphin

The Byford Dolphin was equipped with a saturation diving system, which allowed divers to work at great depths for extended periods. Saturation diving involves pressurizing the divers’ bodies with a mixture of helium and oxygen (heliox) to match the pressure at the working depth. This eliminates the need for lengthy decompression stops after each dive, allowing divers to spend more time working on the seabed. However, saturation diving also carries significant risks, including decompression sickness (the bends) and other pressure-related injuries.

The Fateful Day: November 5, 1983

The Byford Dolphin incident occurred on November 5, 1983, while the rig was operating at the Frigg field in the Norwegian sector of the North Sea. A team of divers was working to connect a pipeline to the platform. The incident involved the rapid and uncontrolled decompression of four divers who were inside a diving bell connected to the rig’s diving system. This catastrophic event resulted in the immediate deaths of all four divers.

Sequence of Events Leading to the Tragedy

Several factors contributed to the Byford Dolphin incident. The primary cause was a failure in the diving system’s interlock mechanism, which was designed to prevent the diving bell from being disconnected from the hyperbaric chamber while the system was still pressurized. The following sequence of events unfolded:

- Divers Edwin Coward, William Crammond, Ronald Lucas, and Helge Løvik were in the diving bell, connected to the diving system via a trunk.

- Two support divers, Martin Saunders and William Brown, were in the living quarters section of the diving system.

- One of the support divers prematurely opened the clamp connecting the diving bell to the diving system.

- This action caused a massive and instantaneous pressure drop from 9 atmospheres to 1 atmosphere.

The Catastrophic Decompression

The rapid decompression had devastating consequences for the divers in the diving bell. The sudden decrease in pressure caused the nitrogen and helium dissolved in their blood and tissues to rapidly form bubbles, leading to severe decompression sickness. The force of the decompression was so extreme that it resulted in gruesome injuries and immediate fatalities.

The Aftermath: Investigation and Findings

Following the Byford Dolphin incident, a comprehensive investigation was launched to determine the cause of the accident and to prevent similar tragedies from occurring in the future. The investigation revealed several critical failures in the design, operation, and safety procedures of the diving system.

Key Findings of the Investigation

- Failure of the Interlock Mechanism: The investigation found that the interlock mechanism, which was supposed to prevent the clamp from being opened while the system was pressurized, had failed. This failure allowed the clamp to be opened prematurely, leading to the catastrophic decompression.

- Human Error: While the failure of the interlock mechanism was the primary cause of the accident, the investigation also identified human error as a contributing factor. The support diver who opened the clamp was found to have violated established safety procedures.

- Inadequate Safety Procedures: The investigation revealed that the safety procedures in place at the time were inadequate to prevent such an accident. There was a lack of clear communication and coordination between the diving team and the rig operators.

- Design Flaws: The design of the diving system itself was found to have several flaws that increased the risk of accidents. The system lacked redundancy and backup mechanisms to prevent failures.

The Human Cost: Remembering the Victims

The Byford Dolphin incident claimed the lives of four divers: Edwin Coward, William Crammond, Ronald Lucas, and Helge Løvik. These men were skilled professionals who dedicated their lives to the challenging and dangerous work of offshore diving. Their deaths serve as a tragic reminder of the risks faced by those who work in the offshore oil and gas industry. It’s essential to remember their sacrifice and to honor their memory by continuing to improve safety standards and prevent similar tragedies from occurring in the future.

Impact on Safety Regulations and Industry Practices

The Byford Dolphin incident had a profound impact on safety regulations and industry practices in the offshore oil and gas industry. The tragedy led to a comprehensive review of safety procedures, equipment design, and training programs. As a result, numerous changes were implemented to improve the safety of diving operations and prevent similar accidents from happening again.

Key Changes Implemented After the Incident

- Improved Interlock Mechanisms: Diving systems were redesigned with more robust and reliable interlock mechanisms to prevent accidental decompression.

- Enhanced Safety Procedures: New safety procedures were implemented to ensure clear communication, coordination, and adherence to established protocols.

- Increased Training: Divers and support personnel received enhanced training to improve their understanding of diving systems and safety procedures.

- Independent Verification: Independent verification and certification of diving systems became mandatory to ensure compliance with safety standards.

- Emergency Procedures: Improved emergency procedures were developed to respond effectively to accidents and minimize the consequences of failures.

The Byford Dolphin Incident and the Importance of Human Factors

Beyond the technical failures, the Byford Dolphin incident highlighted the critical role of human factors in safety. Human error, communication breakdowns, and inadequate training were all contributing factors to the tragedy. As a result, there has been a greater emphasis on understanding and addressing human factors in the offshore oil and gas industry.

Addressing Human Factors in Offshore Operations

- Improved Communication: Clear and effective communication is essential for preventing accidents. Training programs now emphasize the importance of communication skills and teamwork.

- Fatigue Management: Fatigue can impair judgment and increase the risk of errors. Companies have implemented fatigue management programs to ensure that workers are adequately rested.

- Stress Management: Stress can also contribute to errors. Stress management programs are designed to help workers cope with the demands of their jobs.

- Culture of Safety: Creating a culture of safety is essential for preventing accidents. This involves promoting a proactive approach to safety and encouraging workers to report potential hazards.

The Legacy of the Byford Dolphin Incident

The Byford Dolphin incident remains a significant event in the history of the offshore oil and gas industry. It serves as a constant reminder of the dangers inherent in this work and the importance of prioritizing safety above all else. The lessons learned from this tragedy have led to significant improvements in safety regulations, equipment design, and training programs. While the risks associated with offshore operations can never be completely eliminated, the industry has made significant strides in reducing the likelihood of similar accidents occurring in the future.

The Byford Dolphin incident is a complex event with many contributing factors. By understanding the circumstances that led to the tragedy, we can learn valuable lessons about the importance of safety, communication, and human factors in high-risk industries. It is our hope that this article has provided a comprehensive and informative account of the Byford Dolphin incident and its lasting impact on the offshore oil and gas industry.

Expert Perspectives on the Byford Dolphin Incident

Analyzing the Byford Dolphin Incident requires insights from various expert fields, including engineering, diving safety, and organizational management. While direct quotes are unavailable, the following represents a synthesis of expert opinions and findings from investigations and subsequent safety improvements.

Engineering Analysis

Engineering experts have emphasized the critical need for fail-safe mechanisms in diving systems. The lack of redundancy in the interlock system on the Byford Dolphin was a significant design flaw. Modern systems incorporate multiple layers of protection to prevent accidental decompression. Furthermore, materials science plays a role; components must withstand extreme pressures and environmental conditions without failure. Regular inspections and rigorous testing are paramount.

Diving Safety Protocols

Diving safety experts stress the importance of adherence to established protocols and continuous training. The premature opening of the clamp, a direct violation of safety procedures, underscores the need for a strong safety culture. Divers and support personnel must be thoroughly trained on the operation of diving systems, emergency procedures, and the physiological effects of pressure. Clear communication channels and well-defined roles are essential for preventing errors.

Organizational Management and Safety Culture

Experts in organizational management highlight the role of leadership in fostering a safety culture. A top-down commitment to safety, with clear lines of responsibility and accountability, is crucial. Companies must invest in safety training, provide adequate resources for safety programs, and encourage open reporting of potential hazards. A blame-free environment allows workers to report errors without fear of reprisal, facilitating learning and improvement.

Q&A: Addressing Key Questions About the Byford Dolphin Incident

-

Q: What specific type of gas mixture was used in the diving bell, and why?

A: The diving bell used a heliox mixture (helium and oxygen). Helium is used to reduce the nitrogen narcosis effect that occurs at high pressures with nitrogen-based breathing gases. The oxygen content is carefully controlled to prevent oxygen toxicity.

-

Q: What were the immediate physiological effects on the divers due to the rapid decompression?

A: The rapid decompression caused immediate and catastrophic decompression sickness. The dissolved gases in their blood and tissues formed bubbles, leading to tissue damage, arterial gas embolism, and disruption of vital organ function. The speed of decompression amplified these effects exponentially.

-

Q: How has the design of hyperbaric chambers and diving bells changed since the Byford Dolphin incident to improve safety?

A: Modern designs incorporate multiple interlock systems, redundant pressure monitoring, and emergency backup systems. Materials are stronger and more resistant to pressure-related failures. Chamber layouts have been optimized for easier access and emergency egress.

-

Q: What role did the Norwegian Petroleum Directorate (NPD) play in the investigation and subsequent safety improvements?

A: The NPD conducted a thorough investigation of the incident and issued recommendations for safety improvements. They subsequently strengthened regulations and enforcement to ensure compliance with safety standards in the Norwegian sector of the North Sea.

-

Q: What are the long-term psychological effects on divers who work in saturation diving after such incidents?

A: Divers may experience PTSD, anxiety, and depression. The psychological impact can be significant, requiring access to mental health support and counseling services. Many divers may choose to leave the profession altogether.

-

Q: How does current technology mitigate the risks associated with saturation diving compared to the technology available in 1983?

A: Modern technology includes advanced pressure monitoring systems, automated controls, and real-time data analysis. Divers wear sophisticated monitoring equipment that tracks their vital signs and environmental conditions. Remotely operated vehicles (ROVs) are increasingly used to perform tasks that would have previously required divers, reducing human exposure to risk.

-

Q: What specific training protocols are now mandatory for saturation divers that were not in place before the Byford Dolphin incident?

A: Mandatory training now includes comprehensive emergency procedures, advanced decompression techniques, and human factors training. Divers must undergo rigorous simulations and drills to prepare for potential emergencies. Certification requirements have also been significantly strengthened.

-

Q: How has the industry addressed the issue of fatigue and its impact on diver safety since the incident?

A: The industry has implemented fatigue management programs that limit work hours, provide adequate rest periods, and monitor worker alertness. These programs often include education on sleep hygiene and the effects of fatigue on performance. Technology, such as wearable sensors, is being explored to detect signs of fatigue in real-time.

-

Q: What are the current regulations regarding the independent verification of diving systems, and how do they prevent similar incidents?

A: Independent verification involves third-party experts inspecting and certifying diving systems to ensure compliance with safety standards. This process helps identify potential design flaws, operational deficiencies, and maintenance issues. Regular audits and inspections are also conducted to maintain certification.

-

Q: What are the ethical considerations for companies involved in high-risk activities like saturation diving, and how have these considerations evolved since the Byford Dolphin incident?

A: Companies now have a greater ethical responsibility to prioritize safety above all else. This includes providing adequate resources for safety programs, fostering a culture of transparency and accountability, and ensuring that workers are properly trained and equipped. Ethical considerations also extend to providing support for workers and their families in the event of an accident.

Conclusion: Remembering the Past, Ensuring a Safer Future

The Byford Dolphin incident was a tragic event that had a profound impact on the offshore oil and gas industry. It exposed critical flaws in safety procedures, equipment design, and training programs. The lessons learned from this tragedy have led to significant improvements in safety regulations and industry practices. While the risks associated with offshore operations can never be completely eliminated, the industry has made significant strides in reducing the likelihood of similar accidents occurring in the future. It stands as a stark reminder of the constant need for vigilance, rigorous safety protocols, and a commitment to continuous improvement in the pursuit of a safer working environment for all involved in such hazardous industries.

Share your thoughts and perspectives on the Byford Dolphin incident in the comments below. Let’s continue the conversation and work together to ensure a safer future for the offshore oil and gas industry. Explore further resources on diving safety and accident prevention to deepen your understanding of these critical issues.