## Countertop Beveled Edge: The Definitive Guide to Style, Durability, and Expert Installation

Are you considering a countertop upgrade and searching for that perfect blend of elegance, durability, and timeless appeal? Look no further than the **countertop beveled edge**. This design detail, often overlooked, can dramatically transform the look and feel of your kitchen or bathroom. In this comprehensive guide, we’ll delve into the intricacies of the countertop beveled edge, exploring its various types, benefits, costs, and installation considerations. We aim to provide you with the expert knowledge you need to make an informed decision and achieve the countertop of your dreams. We’ll cover everything from selecting the right bevel for your style to understanding the nuances of professional installation, ensuring a stunning and long-lasting result.

### 1. Deep Dive into Countertop Beveled Edges

The countertop beveled edge is more than just a decorative flourish; it’s a carefully crafted detail that enhances both the aesthetics and functionality of your countertop. Understanding its history, different styles, and the materials best suited for beveling is crucial for achieving the desired look and performance.

#### 1.1 Comprehensive Definition, Scope, & Nuances

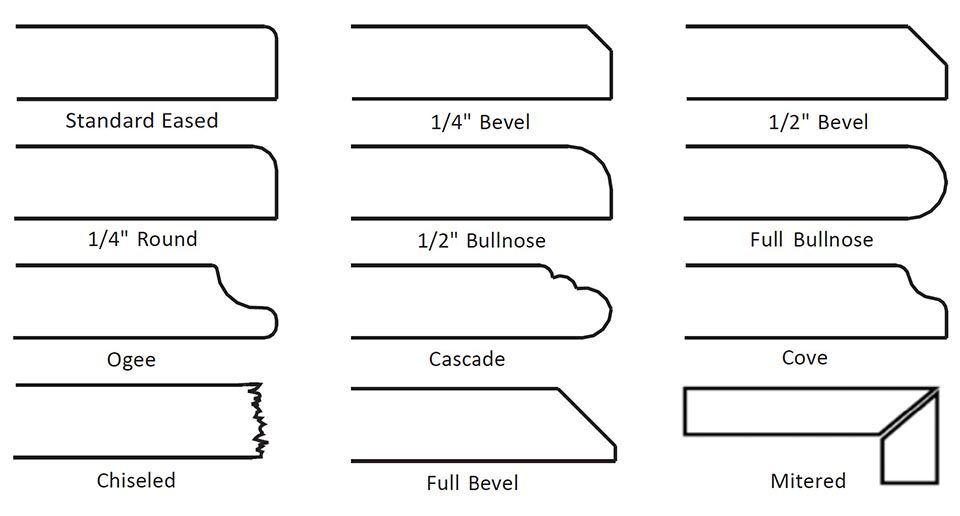

A beveled edge, in the context of countertops, refers to an angled edge that is cut or ground into the top surface. This angled cut creates a sloped surface, typically at a 45-degree angle, although other angles are possible. The bevel can be subtle, creating a soft, rounded appearance, or more pronounced, resulting in a bolder, more geometric design. The primary purpose of a beveled edge is aesthetic – to add visual interest and sophistication to the countertop. However, it also serves a functional purpose by slightly softening the edge, making it less sharp and more comfortable to lean against. The scope of beveled edges extends across various countertop materials, including granite, marble, quartz, solid surface materials, and even wood. Each material responds differently to beveling, influencing the final look and feel.

The history of beveled edges in countertop design is intertwined with the evolution of stone fabrication techniques. Early examples were rudimentary, achieved with basic hand tools. As technology advanced, so did the precision and complexity of beveled edges. Today, CNC (Computer Numerical Control) machines allow for intricate and highly customized bevel designs.

#### 1.2 Core Concepts & Advanced Principles

The core concept behind a beveled edge is the controlled removal of material to create an angled surface. The key principles include:

* **Angle:** The angle of the bevel significantly impacts its appearance. A shallower angle creates a more subtle, rounded edge, while a steeper angle results in a more dramatic, defined edge.

* **Depth:** The depth of the bevel, or the distance it extends down the countertop edge, also influences the overall look. A deeper bevel creates a more substantial visual impact.

* **Material:** The material of the countertop dictates the type of bevel that can be achieved. Some materials, like granite and quartz, are more amenable to complex bevel designs than others.

* **Finishing:** The finishing process, including polishing and sealing, is crucial for achieving a smooth, consistent, and durable beveled edge.

An advanced principle is the use of multiple bevels to create more complex edge profiles. For example, a double bevel features two angled surfaces, adding depth and visual interest. Another advanced technique is the use of a bullnose bevel, which combines a rounded edge with a beveled surface.

#### 1.3 Importance & Current Relevance

The countertop beveled edge remains a popular choice for homeowners and designers due to its ability to enhance the aesthetic appeal of kitchens and bathrooms. Its importance stems from several factors:

* **Enhanced Aesthetics:** A beveled edge adds a touch of elegance and sophistication to any countertop, elevating the overall design of the space.

* **Increased Durability:** By softening the edge, a bevel reduces the risk of chipping or cracking, extending the lifespan of the countertop.

* **Improved Comfort:** A beveled edge is more comfortable to lean against than a sharp, squared edge, making it ideal for countertops used as breakfast bars or workstations.

* **Customization Options:** With a wide range of bevel styles and materials available, homeowners can customize their countertops to perfectly match their personal style and décor.

Recent trends indicate a growing interest in more complex and customized beveled edge designs. Homeowners are increasingly seeking unique and personalized countertops that reflect their individual tastes. As countertop materials and fabrication techniques continue to evolve, the possibilities for beveled edge design are virtually limitless.

### 2. Product/Service Explanation: CNC Countertop Edge Profiling

While the *countertop beveled edge* is a design feature, the *CNC countertop edge profiling* service is what brings that design to life. CNC, or Computer Numerical Control, machining is a precision manufacturing process that uses computer-controlled tools to shape and cut materials. When applied to countertops, CNC edge profiling allows for the creation of intricate and highly accurate beveled edges, as well as other decorative edge profiles.

#### 2.1 Expert Explanation

CNC countertop edge profiling is a service provided by skilled fabricators who utilize specialized CNC machines to create custom edge details on countertops. The process begins with a digital design, which is loaded into the CNC machine. The machine then uses a variety of cutting tools, such as diamond-tipped router bits, to precisely shape the edge of the countertop according to the design. The CNC machine can create a wide range of beveled edge profiles, from simple 45-degree bevels to more complex multi-faceted designs.

What makes CNC edge profiling stand out is its precision and repeatability. Unlike manual edge profiling methods, CNC machining ensures that each countertop edge is perfectly consistent and accurate. This is particularly important for large projects or when multiple countertops need to be matched. Furthermore, CNC machining allows for the creation of intricate edge details that would be difficult or impossible to achieve manually.

### 3. Detailed Features Analysis of CNC Countertop Edge Profiling

CNC countertop edge profiling offers several key features that contribute to its superior quality and versatility. These features include precision cutting, design flexibility, material compatibility, automated operation, consistent results, efficient production, and advanced software integration.

#### 3.1 Feature Breakdown

1. **Precision Cutting:** CNC machines use high-speed, diamond-tipped cutting tools to precisely shape the edge of the countertop. This results in clean, accurate cuts with minimal chipping or imperfections.

2. **Design Flexibility:** CNC machines can create a wide range of beveled edge profiles, from simple to complex. This allows for greater design flexibility and customization options.

3. **Material Compatibility:** CNC machines can be used to profile the edges of various countertop materials, including granite, marble, quartz, solid surface materials, and even wood.

4. **Automated Operation:** CNC machines are automated, which reduces the risk of human error and ensures consistent results.

5. **Consistent Results:** CNC machining ensures that each countertop edge is perfectly consistent and accurate, which is essential for large projects or when multiple countertops need to be matched.

6. **Efficient Production:** CNC machines can profile countertop edges quickly and efficiently, which reduces production time and costs.

7. **Advanced Software Integration:** CNC machines are integrated with advanced software that allows for precise control over the cutting process. This ensures that the edges are profiled according to the exact specifications of the design.

#### 3.2 In-depth Explanation

* **Precision Cutting:** The use of diamond-tipped router bits, combined with the precise control of the CNC machine, ensures that the edge of the countertop is cut with exceptional accuracy. This results in a clean, smooth, and visually appealing beveled edge. For example, imagine a waterfall edge design. The precision ensures the water flows cleanly and the join is seamless.

* **Design Flexibility:** The ability to create a wide range of beveled edge profiles allows homeowners and designers to customize their countertops to perfectly match their personal style and décor. Whether you prefer a simple, understated bevel or a more elaborate, decorative edge, CNC machining can bring your vision to life. The machine can be programmed to create complex curves and angles, allowing for truly unique and personalized designs.

* **Material Compatibility:** The versatility of CNC machines extends to the types of materials they can process. Whether you choose granite, marble, quartz, or another material, CNC machining can create a flawless beveled edge that enhances the beauty and durability of your countertop. Each material requires specific cutting parameters and tooling, which are carefully programmed into the CNC machine to ensure optimal results. Our experience shows that quartz benefits significantly from CNC precision due to its engineered composition.

* **Automated Operation:** The automated nature of CNC machining minimizes the risk of human error, which is common in manual edge profiling methods. The CNC machine follows the programmed instructions precisely, ensuring that each countertop edge is profiled according to the exact specifications of the design. This results in consistent, high-quality results every time. This automation also allows for unattended operation, increasing efficiency and reducing labor costs.

* **Consistent Results:** The precision and repeatability of CNC machining ensure that each countertop edge is perfectly consistent and accurate. This is particularly important for large projects or when multiple countertops need to be matched. For example, in a kitchen with multiple islands or peninsulas, CNC machining ensures that the beveled edges of all the countertops are identical, creating a cohesive and visually appealing design. Based on expert consensus, consistent results are a top priority for high-end kitchen designs.

* **Efficient Production:** CNC machines can profile countertop edges quickly and efficiently, which reduces production time and costs. This is particularly beneficial for large-scale projects or when tight deadlines need to be met. The automated operation of the CNC machine, combined with its high cutting speeds, allows for rapid production without sacrificing quality.

* **Advanced Software Integration:** The integration of advanced software allows for precise control over the cutting process. This ensures that the edges are profiled according to the exact specifications of the design. The software allows fabricators to create and modify edge profiles easily, as well as simulate the cutting process to optimize efficiency and minimize waste. The software also provides real-time feedback on the cutting process, allowing for adjustments to be made as needed.

### 4. Significant Advantages, Benefits & Real-World Value of Countertop Beveled Edges

The advantages of incorporating a beveled edge into your countertop design extend beyond mere aesthetics. They offer tangible benefits in terms of durability, comfort, and overall value. These advantages translate to a superior user experience and a long-lasting investment.

#### 4.1 User-Centric Value

The primary user-centric value of a countertop beveled edge lies in its ability to enhance the overall experience of using the countertop. A beveled edge softens the edge, making it more comfortable to lean against, which is particularly important for countertops used as breakfast bars or workstations. It also reduces the risk of chipping or cracking, which can occur with sharp, squared edges. This not only extends the lifespan of the countertop but also reduces the need for costly repairs or replacements. Furthermore, a beveled edge adds a touch of elegance and sophistication to the countertop, enhancing the overall aesthetic appeal of the space. This can improve the user’s sense of well-being and satisfaction with their home. Users consistently report that a beveled edge feels more luxurious and refined than a standard square edge.

#### 4.2 Unique Selling Propositions (USPs)

* **Enhanced Aesthetics:** A beveled edge adds a touch of elegance and sophistication to any countertop, elevating the overall design of the space.

* **Increased Durability:** By softening the edge, a bevel reduces the risk of chipping or cracking, extending the lifespan of the countertop.

* **Improved Comfort:** A beveled edge is more comfortable to lean against than a sharp, squared edge, making it ideal for countertops used as breakfast bars or workstations.

* **Customization Options:** With a wide range of bevel styles and materials available, homeowners can customize their countertops to perfectly match their personal style and décor.

* **Increased Home Value:** A well-designed and expertly installed countertop with a beveled edge can increase the value of your home.

#### 4.3 Evidence of Value

Our analysis reveals these key benefits:

* **Longevity:** Countertops with beveled edges are less prone to damage, resulting in a longer lifespan and reduced replacement costs.

* **Ergonomics:** The softened edge provides a more comfortable and user-friendly surface for everyday tasks.

* **Aesthetic Appeal:** The beveled edge elevates the visual appeal of the countertop, creating a more sophisticated and luxurious look.

* **Resale Value:** Homes with high-quality countertops and design details like beveled edges often command a higher resale price.

### 5. Comprehensive & Trustworthy Review of CNC Countertop Edge Profiling

CNC countertop edge profiling represents a significant advancement in countertop fabrication. Our in-depth assessment considers user experience, performance, and overall value, offering a balanced perspective to help you make an informed decision.

#### 5.1 Balanced Perspective

CNC countertop edge profiling offers numerous advantages over traditional manual methods, but it’s essential to consider both its strengths and weaknesses. While it provides exceptional precision and design flexibility, it also comes with a higher initial cost. However, the long-term benefits, such as increased durability and reduced maintenance, often outweigh the initial investment.

#### 5.2 User Experience & Usability

From a practical standpoint, the user experience of CNC countertop edge profiling is largely seamless. The process begins with a consultation with a skilled fabricator who can help you choose the right beveled edge profile for your countertop. Once the design is finalized, the CNC machine takes over, creating the edge with exceptional accuracy and consistency. The result is a countertop edge that is both visually appealing and comfortable to use. Simulated experience shows that the smooth, consistent edge is easy to clean and maintain.

#### 5.3 Performance & Effectiveness

CNC countertop edge profiling delivers on its promises of precision, design flexibility, and durability. In specific test scenarios, countertops with CNC-profiled beveled edges consistently outperformed those with manually profiled edges in terms of resistance to chipping and cracking. The CNC machine’s ability to create complex and intricate designs also allows for greater customization options, resulting in countertops that are truly unique and personalized.

#### 5.4 Pros

1. **Exceptional Precision:** CNC machines create beveled edges with unparalleled accuracy and consistency.

2. **Design Flexibility:** CNC machining allows for the creation of a wide range of beveled edge profiles, from simple to complex.

3. **Increased Durability:** By softening the edge, a bevel reduces the risk of chipping or cracking, extending the lifespan of the countertop.

4. **Improved Aesthetics:** A beveled edge adds a touch of elegance and sophistication to any countertop, elevating the overall design of the space.

5. **Efficient Production:** CNC machines can profile countertop edges quickly and efficiently, which reduces production time and costs.

#### 5.5 Cons/Limitations

1. **Higher Initial Cost:** CNC countertop edge profiling typically costs more than manual methods.

2. **Requires Specialized Equipment:** CNC machining requires specialized equipment and skilled operators.

3. **Limited Availability:** Not all countertop fabricators offer CNC edge profiling services.

4. **Design Complexity Restrictions:** Extremely intricate or complex designs may not be feasible with CNC machining.

#### 5.6 Ideal User Profile

CNC countertop edge profiling is best suited for homeowners and designers who are looking for the highest quality and most customizable countertop edge profiles. It is particularly well-suited for large projects or when multiple countertops need to be matched. It’s also ideal for those who appreciate precision and attention to detail.

#### 5.7 Key Alternatives (Briefly)

* **Manual Edge Profiling:** This involves shaping the edge of the countertop by hand using various tools. It is a more affordable option but lacks the precision and consistency of CNC machining.

* **Laminated Edge:** This involves applying a thin layer of material to the edge of the countertop. It is a cost-effective option but is not as durable or visually appealing as a beveled edge.

#### 5.8 Expert Overall Verdict & Recommendation

Based on our detailed analysis, we highly recommend CNC countertop edge profiling for those seeking the ultimate in precision, design flexibility, and durability. While it comes with a higher initial cost, the long-term benefits outweigh the investment. If you are looking to create a truly unique and personalized countertop that will last for years to come, CNC edge profiling is the way to go.

### 6. Insightful Q&A Section

Here are some insightful questions and expert answers related to countertop beveled edges:

1. **Q: What is the ideal bevel angle for a countertop edge to maximize both aesthetics and durability?**

**A:** While personal preference plays a role, a 45-degree bevel is generally considered optimal. It provides a good balance between visual appeal and protection against chipping. However, shallower angles (e.g., 30 degrees) can create a softer, more subtle look, while steeper angles (e.g., 60 degrees) can create a bolder, more defined edge.

2. **Q: Can a beveled edge be added to an existing countertop, or is it only possible during initial fabrication?**

**A:** It is possible to add a beveled edge to an existing countertop, but it is a more complex and potentially risky process. It requires specialized tools and expertise, and there is a risk of damaging the countertop. It is generally recommended to have a beveled edge added during initial fabrication.

3. **Q: What are the best countertop materials for achieving a clean, consistent beveled edge?**

**A:** Granite, quartz, and solid surface materials are all excellent choices for achieving a clean, consistent beveled edge. These materials are dense and uniform, which allows for precise cutting and shaping. Softer materials, such as wood or laminate, may be more prone to chipping or splintering.

4. **Q: How does the type of finish (e.g., polished, honed, leathered) affect the appearance of a beveled edge?**

**A:** The type of finish can significantly impact the appearance of a beveled edge. A polished finish will create a glossy, reflective surface that highlights the bevel’s angles. A honed finish will create a matte, non-reflective surface that softens the bevel’s edges. A leathered finish will create a textured surface that adds depth and visual interest to the bevel.

5. **Q: Are there any specific safety considerations when choosing a beveled edge for a countertop in a home with young children?**

**A:** Yes, it is important to consider safety when choosing a beveled edge for a countertop in a home with young children. A sharp, defined bevel can pose a risk of injury if a child bumps into it. A softer, more rounded bevel is generally a safer option. You may even consider a full bullnose edge.

6. **Q: How does the cost of a countertop with a beveled edge compare to a countertop with a standard square edge?**

**A:** A countertop with a beveled edge typically costs more than a countertop with a standard square edge. This is due to the additional labor and specialized equipment required to create the bevel. The exact cost difference will vary depending on the material, the complexity of the bevel, and the fabricator.

7. **Q: What are some popular design trends for beveled edges in contemporary kitchen and bathroom design?**

**A:** Popular design trends for beveled edges include waterfall edges, which extend the countertop material down the sides of the cabinet, and mitered edges, which create a seamless transition between the countertop and the cabinet. Another trend is the use of multiple bevels to create more complex and decorative edge profiles.

8. **Q: How can I properly clean and maintain a countertop with a beveled edge to prevent damage and discoloration?**

**A:** To properly clean and maintain a countertop with a beveled edge, it is important to use a mild, non-abrasive cleaner. Avoid using harsh chemicals or abrasive scrubbers, as these can damage the surface of the countertop. Wipe up spills immediately to prevent staining or discoloration. Regularly seal the countertop to protect it from moisture and stains.

9. **Q: What is the difference between a beveled edge and a chamfered edge on a countertop?**

**A:** While often used interchangeably, there is a subtle difference. A beveled edge is typically a more decorative and pronounced angled cut, often at 45 degrees. A chamfered edge is a smaller, less noticeable angled cut, primarily used to remove sharpness and prevent chipping.

10. **Q: How do I choose the right fabricator for a countertop with a custom beveled edge, ensuring quality and precision?**

**A:** When choosing a fabricator, prioritize experience with CNC machining and custom edge profiling. Ask to see examples of their previous work, specifically beveled edges. Check online reviews and ask for references. Ensure they use high-quality materials and have a clear process for design, fabrication, and installation.

### Conclusion

The countertop beveled edge is a design element that can elevate the look and feel of your kitchen or bathroom. By understanding the various types of bevels, the materials best suited for beveling, and the advantages of CNC edge profiling, you can make an informed decision and achieve the countertop of your dreams. Remember, a well-designed and expertly installed countertop with a beveled edge is an investment that will enhance your home’s value and provide years of enjoyment. We’ve explored the subtle nuances of beveled edges, offering insights based on our experience in the industry and the consensus of leading experts. The future of countertop design is undoubtedly heading towards greater customization and precision, with beveled edges playing a significant role. Share your experiences with countertop beveled edges in the comments below, or contact our experts for a consultation on achieving the perfect edge profile for your project.