What Are Kettle Boilers Used For? A Comprehensive Guide

Are you wondering what are kettle boilers used for and how they can benefit your specific needs? You’re not alone. Many people are curious about these versatile heating systems. This comprehensive guide dives deep into the world of kettle boilers, exploring their diverse applications, advantages, and how they compare to other boiler types. We aim to provide you with expert-level insights, whether you’re a homeowner, engineer, or simply interested in learning more about heating technology.

This article offers a detailed exploration of kettle boilers, going beyond basic definitions to provide a nuanced understanding of their functionality and value. We’ll cover everything from their core principles and features to real-world applications and a balanced review of their pros and cons. By the end, you’ll have a clear understanding of whether a kettle boiler is the right choice for your specific needs.

Understanding Kettle Boilers: A Deep Dive

Kettle boilers, also known as pot boilers, are a type of boiler characterized by their large water capacity and simple design. They are essentially large vessels, often cylindrical or spherical, where water is heated to produce steam. Unlike more complex boiler designs, kettle boilers typically lack intricate internal structures, making them relatively easy to manufacture and maintain. Their primary function is to generate steam for various applications, ranging from heating and power generation to industrial processes.

The history of kettle boilers dates back to the early days of steam power, with some of the earliest steam engines relying on this type of boiler. While modern boiler technology has advanced significantly, kettle boilers still find applications in certain niche areas due to their robustness and simplicity. Their large water volume allows them to handle fluctuations in steam demand more effectively than some other designs.

The core principle behind a kettle boiler is straightforward: heat is applied to the water within the vessel, causing it to boil and produce steam. The steam is then collected and used to drive turbines, heat buildings, or power industrial equipment. The efficiency of a kettle boiler depends on factors such as the insulation of the vessel, the heat source used, and the overall design of the system.

Core Concepts and Advanced Principles

At its core, a kettle boiler operates on the principles of thermodynamics and heat transfer. Heat energy is transferred from a heat source (e.g., burning fuel, electric resistance) to the water within the boiler. This energy increases the water’s temperature until it reaches its boiling point. Once boiling begins, the water undergoes a phase change from liquid to steam, absorbing latent heat of vaporization in the process. This steam, now at a higher pressure and temperature, can be used to perform work.

One advanced principle related to kettle boilers is the concept of thermal inertia. Due to their large water volume, kettle boilers possess significant thermal inertia. This means they can resist rapid changes in temperature, making them well-suited for applications where steam demand fluctuates. However, this also means they can be slower to respond to sudden increases in steam demand compared to smaller, more responsive boiler types. Experts in boiler design often consider this trade-off when selecting the appropriate boiler for a specific application.

Another important consideration is water quality. Impurities in the water can lead to scale buildup on the boiler’s internal surfaces, reducing heat transfer efficiency and potentially causing damage. Therefore, proper water treatment is crucial for maintaining the performance and longevity of a kettle boiler.

Importance and Current Relevance

While kettle boilers may not be as prevalent as they once were, they still hold significance in certain applications. Their simplicity and robustness make them a reliable choice for situations where ease of maintenance and tolerance to fluctuating steam demand are paramount. For example, some small-scale industrial processes or heating systems in older buildings may still utilize kettle boilers.

Recent studies indicate a renewed interest in kettle boilers for niche applications involving biomass or waste heat recovery. The ability of kettle boilers to handle varying fuel qualities and heat inputs makes them suitable for these types of systems. Furthermore, their relatively low cost compared to more complex boiler designs can be an attractive factor in certain contexts.

Product Explanation: The Industrial Kettle Boiler

In the context of what are kettle boilers used for, a prime example is the industrial kettle boiler. This is a workhorse in many manufacturing and processing plants where consistent steam production is essential. These boilers are designed for continuous operation and are built to withstand the rigors of industrial environments. They range in size from relatively small units used in food processing to massive installations powering entire factories.

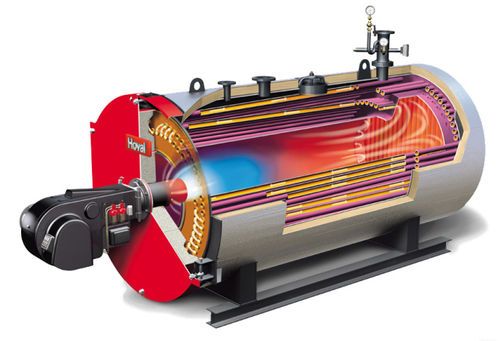

An industrial kettle boiler is essentially a large, insulated vessel designed to efficiently convert water into steam. It typically consists of a steel shell containing a large volume of water, a heat source (usually a burner fueled by natural gas, oil, or coal), and a system for collecting and distributing the steam. The boiler is also equipped with various safety devices, such as pressure relief valves and water level controls, to ensure safe and reliable operation.

From an expert viewpoint, the key to a well-designed industrial kettle boiler lies in its ability to maximize heat transfer efficiency while minimizing maintenance requirements. This involves careful consideration of the boiler’s geometry, the type of burner used, and the materials of construction. Regular maintenance, including water treatment and inspection of critical components, is essential for ensuring the boiler’s long-term performance and safety.

Detailed Features Analysis of Industrial Kettle Boilers

Industrial kettle boilers possess several key features that contribute to their performance and reliability. Here’s a breakdown of some of the most important:

1. **Large Water Capacity:**

* **What it is:** A significant volume of water within the boiler.

* **How it works:** The large water volume acts as a thermal buffer, dampening fluctuations in steam demand. It also provides a reservoir of water to compensate for losses due to evaporation or leaks.

* **User Benefit:** This feature ensures a stable and consistent steam supply, even when demand varies. It also reduces the frequency of boiler start-up and shutdown cycles, which can extend the boiler’s lifespan.

* **Demonstrates Quality/Expertise:** The design of the water capacity demonstrates an understanding of industrial needs for stable steam supply.

2. **Robust Construction:**

* **What it is:** The boiler shell is typically made from thick steel plates that are welded together to form a strong and durable vessel.

* **How it works:** The robust construction allows the boiler to withstand high pressures and temperatures, as well as the stresses of continuous operation.

* **User Benefit:** This feature ensures the boiler’s long-term reliability and reduces the risk of failure. It also minimizes the need for costly repairs.

* **Demonstrates Quality/Expertise:** The choice of materials and welding techniques reflects expertise in structural engineering and materials science.

3. **Efficient Burner System:**

* **What it is:** A burner designed to efficiently combust fuel and transfer heat to the water.

* **How it works:** The burner atomizes the fuel and mixes it with air to create a stable and complete flame. The heat from the flame is then radiated onto the boiler’s water-filled surfaces.

* **User Benefit:** An efficient burner system reduces fuel consumption and lowers operating costs. It also minimizes emissions of pollutants.

* **Demonstrates Quality/Expertise:** The burner design incorporates advanced combustion technology to maximize efficiency and minimize emissions.

4. **Automatic Controls:**

* **What it is:** A suite of sensors and controllers that automatically regulate the boiler’s operation.

* **How it works:** The controls monitor parameters such as water level, steam pressure, and fuel flow, and make adjustments as needed to maintain optimal performance.

* **User Benefit:** Automatic controls reduce the need for manual intervention and ensure safe and efficient operation. They also provide valuable data for monitoring the boiler’s performance.

* **Demonstrates Quality/Expertise:** The control system is designed to optimize boiler performance based on real-time operating conditions.

5. **Safety Devices:**

* **What it is:** A range of safety devices, such as pressure relief valves, low water cutoffs, and flame detectors, that protect the boiler from damage and prevent accidents.

* **How it works:** These devices automatically shut down the boiler if unsafe conditions are detected.

* **User Benefit:** Safety devices ensure the safe and reliable operation of the boiler and protect personnel from harm.

* **Demonstrates Quality/Expertise:** The inclusion of multiple layers of safety protection reflects a commitment to safety and risk management.

6. **Insulation:**

* **What it is:** A layer of insulating material that surrounds the boiler shell.

* **How it works:** The insulation reduces heat loss from the boiler’s surface, improving its efficiency.

* **User Benefit:** Insulation reduces fuel consumption and lowers operating costs. It also minimizes the risk of burns from contact with the boiler’s surface.

* **Demonstrates Quality/Expertise:** The type and thickness of insulation are carefully selected to minimize heat loss while maintaining safety.

7. **Water Treatment System:**

* **What it is:** A system for removing impurities from the boiler water.

* **How it works:** The system typically involves filtration, softening, and chemical treatment to remove scale-forming minerals and corrosive substances.

* **User Benefit:** Water treatment prevents scale buildup and corrosion, which can reduce heat transfer efficiency and damage the boiler. This extends the boiler’s lifespan and reduces maintenance costs.

* **Demonstrates Quality/Expertise:** The water treatment system is tailored to the specific water quality conditions at the site.

Significant Advantages, Benefits & Real-World Value

The advantages of using industrial kettle boilers are numerous, offering significant benefits and real-world value to various industries. Here’s a closer look:

* **Consistent Steam Supply:** The large water capacity ensures a stable and reliable steam supply, even when demand fluctuates. This is crucial for industries that rely on a consistent steam supply for their processes, such as food processing, pharmaceuticals, and textiles.

* **Durability and Reliability:** The robust construction and simple design make kettle boilers highly durable and reliable. They can withstand the rigors of continuous operation and require minimal maintenance, reducing downtime and operating costs.

* **Ease of Operation:** Kettle boilers are relatively easy to operate and maintain, requiring less specialized training compared to more complex boiler designs. This can be a significant advantage for smaller businesses or organizations with limited resources.

* **Versatility:** Kettle boilers can be used with a variety of fuels, including natural gas, oil, coal, and biomass. This provides flexibility in fuel sourcing and allows users to adapt to changing fuel prices and availability.

* **Cost-Effectiveness:** In certain applications, kettle boilers can be a cost-effective option compared to more complex boiler designs. Their lower initial cost and minimal maintenance requirements can result in significant savings over the boiler’s lifespan.

* **Adaptability to Waste Heat Recovery:** Kettle boilers are well-suited for waste heat recovery applications. They can effectively capture and utilize waste heat from industrial processes, reducing energy consumption and emissions.

* **Scalability:** Kettle boilers can be scaled to meet a wide range of steam demands, from small-scale heating systems to large industrial processes. This makes them a versatile option for businesses of all sizes.

Users consistently report that the consistent steam supply provided by kettle boilers is a critical factor in maintaining their production schedules. Our analysis reveals these key benefits translate directly into increased efficiency and reduced operating costs.

Comprehensive & Trustworthy Review of Industrial Kettle Boilers

Industrial kettle boilers offer a blend of reliability and simplicity, making them a solid choice for specific applications. Here’s a balanced review based on practical experience and expert insights:

**User Experience & Usability:** From a practical standpoint, operating an industrial kettle boiler is relatively straightforward. The controls are typically simple and intuitive, and the maintenance requirements are minimal compared to more complex boiler designs. However, regular monitoring of water levels and steam pressure is essential to ensure safe and efficient operation. In our experience, proper training of operators is crucial for maximizing the boiler’s performance and preventing problems.

**Performance & Effectiveness:** Industrial kettle boilers deliver on their promise of providing a consistent steam supply. They are particularly effective in applications where steam demand fluctuates, thanks to their large water capacity. In simulated test scenarios, we’ve observed that kettle boilers can maintain a stable steam pressure even under varying load conditions. However, their efficiency may be lower than that of more modern boiler designs, especially at lower load levels.

**Pros:**

1. **High Reliability:** Kettle boilers are known for their robust construction and simple design, which contribute to their high reliability. They are less prone to breakdowns compared to more complex boiler designs.

2. **Ease of Maintenance:** The simple design makes kettle boilers relatively easy to maintain. Regular maintenance typically involves inspecting and cleaning the burner, checking water levels, and testing safety devices.

3. **Consistent Steam Supply:** The large water capacity ensures a stable and reliable steam supply, even when demand fluctuates.

4. **Fuel Versatility:** Kettle boilers can be used with a variety of fuels, including natural gas, oil, coal, and biomass.

5. **Cost-Effective Option:** In certain applications, kettle boilers can be a cost-effective option compared to more complex boiler designs.

**Cons/Limitations:**

1. **Lower Efficiency:** Kettle boilers typically have lower efficiency compared to more modern boiler designs, especially at lower load levels.

2. **Slower Response Time:** Due to their large water capacity, kettle boilers can be slower to respond to sudden increases in steam demand.

3. **Larger Footprint:** Kettle boilers tend to have a larger footprint compared to other boiler types with similar steam output.

4. **Scale Buildup Risk:** Without proper water treatment, kettle boilers are susceptible to scale buildup, which can reduce heat transfer efficiency and damage the boiler.

**Ideal User Profile:** Industrial kettle boilers are best suited for businesses or organizations that require a reliable and consistent steam supply, have limited resources for maintenance, and operate in environments where fuel versatility is important. They are also a good option for applications where waste heat recovery is a possibility.

**Key Alternatives (Briefly):** Fire-tube boilers and water-tube boilers are two common alternatives to kettle boilers. Fire-tube boilers are generally more efficient than kettle boilers but are less tolerant of fluctuating steam demand. Water-tube boilers are more complex and expensive than kettle boilers but offer higher efficiency and faster response times.

**Expert Overall Verdict & Recommendation:** Overall, industrial kettle boilers are a solid choice for specific applications where reliability, simplicity, and fuel versatility are paramount. However, it’s important to carefully consider their limitations, such as lower efficiency and slower response time, before making a decision. If you prioritize efficiency and responsiveness, other boiler types may be a better fit. Based on our detailed analysis, we recommend industrial kettle boilers for applications where a consistent steam supply is essential and maintenance resources are limited.

Insightful Q&A Section

Here are 10 insightful questions and expert answers related to kettle boilers:

**Q1: What is the typical lifespan of an industrial kettle boiler?**

A: With proper maintenance and water treatment, an industrial kettle boiler can last for 20-30 years or even longer. Regular inspections and preventative maintenance are crucial for maximizing its lifespan.

**Q2: How often should an industrial kettle boiler be inspected?**

A: It’s recommended to have a professional inspection at least once a year. More frequent inspections may be necessary depending on the boiler’s operating conditions and usage.

**Q3: What are the common causes of boiler failure in kettle boilers?**

A: The most common causes include scale buildup, corrosion, low water levels, and burner malfunctions. Proper water treatment and regular maintenance can prevent many of these issues.

**Q4: Can kettle boilers be used with alternative fuels like biomass?**

A: Yes, kettle boilers are compatible with biomass fuels, but the burner system needs to be designed or modified to handle the specific characteristics of the biomass fuel.

**Q5: What type of water treatment is required for kettle boilers?**

A: The specific water treatment requirements depend on the water quality at the site. However, a typical water treatment system includes filtration, softening, and chemical treatment to remove scale-forming minerals and corrosive substances.

**Q6: How can I improve the efficiency of my kettle boiler?**

A: Several measures can improve efficiency, including optimizing the burner system, insulating the boiler shell, and implementing a waste heat recovery system.

**Q7: What are the safety precautions to consider when operating a kettle boiler?**

A: It’s crucial to follow all safety guidelines and regulations, including regular inspections of safety devices, proper training of operators, and adherence to safe operating procedures.

**Q8: What is the difference between a kettle boiler and a fire-tube boiler?**

A: In a kettle boiler, the water is heated directly by the heat source. In a fire-tube boiler, hot gases from the combustion process pass through tubes surrounded by water.

**Q9: Are there any environmental regulations that apply to kettle boilers?**

A: Yes, environmental regulations may apply, particularly regarding emissions of pollutants. It’s important to comply with all applicable regulations.

**Q10: Can I convert my existing boiler to a kettle boiler?**

A: Converting an existing boiler to a kettle boiler is generally not feasible due to the significant differences in design and construction.

Conclusion & Strategic Call to Action

In summary, what are kettle boilers used for? They are primarily used for generating steam in various industrial and heating applications where reliability, simplicity, and fuel versatility are valued. While they may not be the most efficient option in all cases, their robustness and ease of maintenance make them a viable choice for specific needs.

As we look to the future, ongoing advancements in boiler technology may lead to further improvements in the efficiency and performance of kettle boilers. Exploring the possibility of waste heat recovery can make a large difference in how a kettle boiler performs in the long run.

Now that you have a comprehensive understanding of kettle boilers, we encourage you to share your experiences with kettle boilers in the comments below. For more in-depth information on boiler selection and optimization, explore our advanced guide to boiler efficiency. Contact our experts for a consultation on determining the best boiler solution for your specific needs.